|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Quality and tolerance testing | >Measurement is child's play |

Measurement is child's play

12 September 2015

To achieve maximum efficiency in its automated operation, Playmobil's numerous machining centres use LaserControl measuring systems from Blum-Novotest.

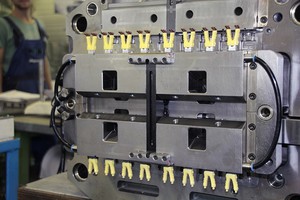

For the precisely engineered Playmobil figures, hundredths of a millimetre count. The aim in making the injection moulds is to output a finished plastic item with practically no reworking.

"The machines even keep running unmanned over the weekend, that degree of automation would not be possible without the Blum laser systems. The Blum-Novotest systems are installed in the workshop on our nine automated DMG five-axis machining centres," stresses Marco Mendl, team leader CAD/CAM/NC.

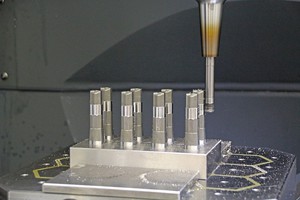

After every tool change, the laser automatically measures the length and radius of the tool prior to machining and after machining checks for breakage and wear. This saves the experts having to pre-set the tool in the presetting device.

A new tool is simply shrink-fitted into the holder and measured at machining speed after fitting. This ensures that the tool data in the machine is correct, numerical errors or mistakes reading off data can no longer occur. Further features include high-speed automatic compensation for the thermal expansion of the complete machine and for spindle displacement.

"Five years ago I would have still been saying that it is impossible to incorporate the complete tool measurement process into the machine, but now it works like a dream," comments Mendl. "We have had only good experiences with Blum lasers – and we save on working time because there is no need for pre-setting. The accuracy of the LaserControl system is astounding too. Based on our experience, its repeatability is within less than two thousandths of a millimetre."

At Playmobil, as many as four of the key tools are held in the tool changer, meaning the automated overnight jobs run highly reliably. If the laser detects that the tool is worn after machining, a twin replacement tool is automatically loaded. High chromium content steel is mostly used because it wears less when injection-moulding large quantities. "It does cause considerable tool wear during cutting. That is why it is very important to keep an eye on the running times of the individual tools.

The Blum laser measuring systems enable us to do that very well," Attila Britting adds. High-precision measurement in a dirty environment poses a major challenge, and coolant is essential to the production process. To protect the optic from being soiled, the measuring system is mechanically sealed off from the coolant by a pneumatically operated shutter piston during machining.

The rotating tool is also cleaned with compressed air prior to measuring, to ensure that the measurement is not influenced by swarf, dirt or cooling lubricant. During measurement, a stream of barrier air provides protection against soiling.

On the five-axis machines, the moulds are wherever possible cut in a work-holder fixture, in order to achieve maximum possible accuracy. Often very small tools are used, capable of reaching into the most difficult corners of the mould. On the nine automated DMG machining centres, tools from the 0.5mm ball cutter up to the 50mm milling head are deployed.

On the two Röders machining centres used to produce the graphite electrodes, the range extends down to the 0.25mm ball cutter. Only PCD tools are used on these machining centres, the diversity of tool variants poses no problem for Blum LaserControl systems.