|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Valves and actuators | >Valve safety & efficiency enhanced |

Valve safety & efficiency enhanced

12 December 2015

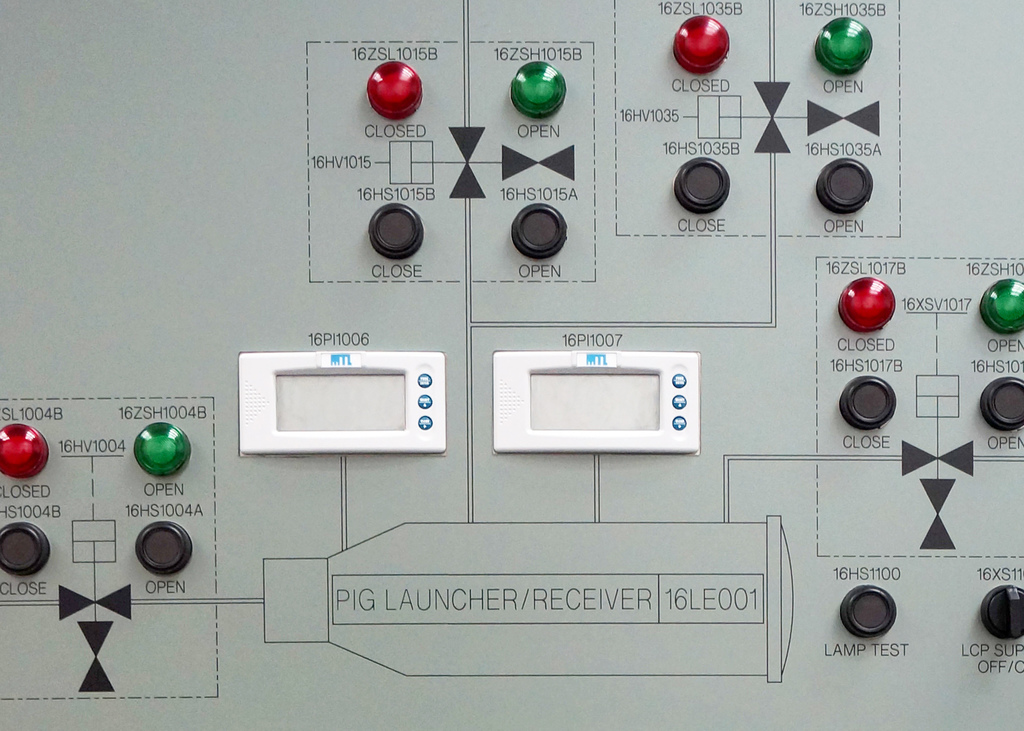

When oil & gas company Eni Norge wanted to simplify its valve processes on the Goliat Field oilfield, Smith Flow Control provided a solution by developing a custom-built operating panel that enhances safety and increases efficiency. It does this by moving the control and operation of Eni Norge’s large number of valves to a single, safe location.

The electronic operating panel works as a communication and verification system and enables an operator to control a sequence of actuated valves directly from the panel. Two operating panels were installed on a Floating Production, Storage and Offloading vessel built-for-use on the Goliat Field, the first oilfield to be developed in the Barents Sea.

Although the operating panel can be used in a wide variety of applications, in this case the panel was specifically designed for use with a pigging procedure. Each panel controlled four valves and incorporated two mechanical interlock key units to ensure a specific sequence of operation.