|

Edward Lowton

Editor |

|

Swift motor replacement

29 January 2016

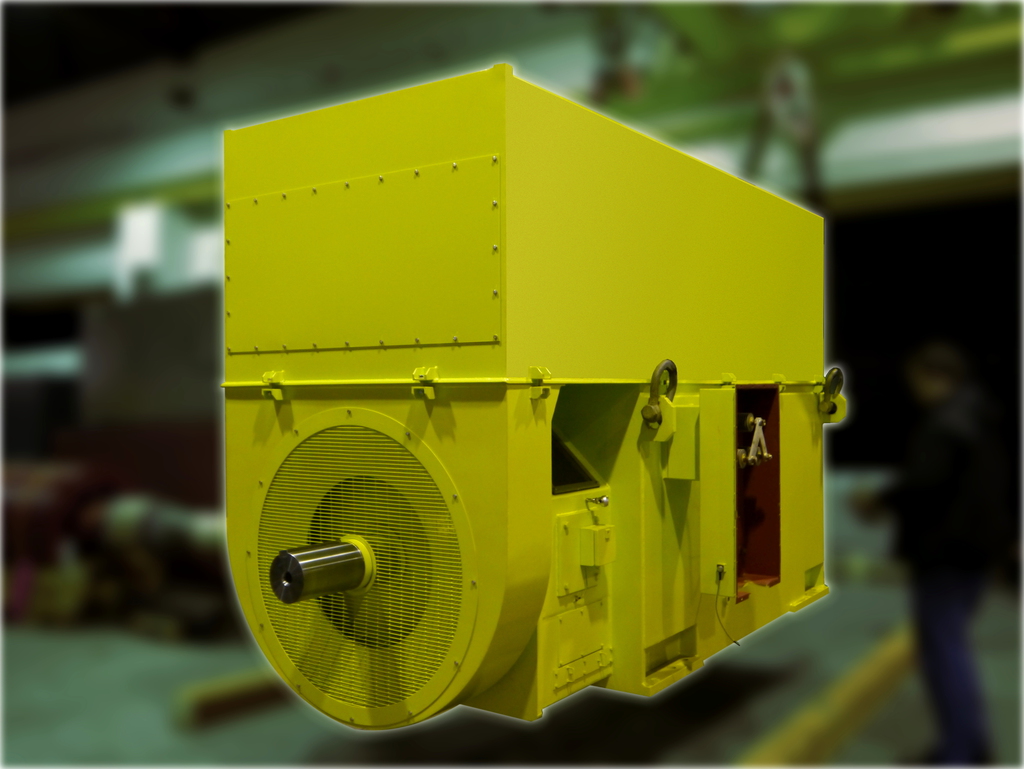

In November 2015, electric motor manufacturer Menzel Elektromotoren ended a serious production interruption at a cement plant in Cambridge. Three days after the failure of both the mill drive and the existing reserve motor, the plant operators faced a full-scale production shutdown.

On the Friday night, they turned to Menzel with a request for the construction and delivery of a replacement motor – and by Monday, a new identical motor with customised modifications had already left Menzel Berlin's workshop. Prolonged and costly production downtime was averted.

Such a quick response was possible mainly due to Menzel's stock of more than 20,000 motors in a power range to 15,000kW. A suitable slip ring motor with 2300kW, 11,000V nominal voltage and a speed of 992 min-¹ that matched the original motor's features – namely constantly running brushes, roller bearings for grease lubrication, and two free shaft ends – was readily available. The availability of in-house load test fields at Menzel also contributed substantially to the fast delivery time.

- Six days instead of six months delivery

- Menzel is top of the game!

- Big compressor motor customised for 15-ton crane

- Despite coronavirus: Large inventory of motors ex stock

- Cement mill motor in economic 1-for-3 design

- Explosion-proof compressor motor for oil refinery

- Menzel supplies pump drives in special configuration

- Efficiency: putting motors through their paces

- New Menzel motor plant completed

- Motors for swift shipping

- No related articles listed