|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Quality and tolerance testing | >Rapid 2D measurement |

Rapid 2D measurement

30 March 2016

Featuring intelligent Saphir QD software combined with the speed of the VideoCAD Rapid measurement station, the VideoCAD Rapid high definition 2D measurement device is claimed to be ideal for manufacturers of multiple and varied components such as stampings, pressed metal parts, gaskets, gears and cams.

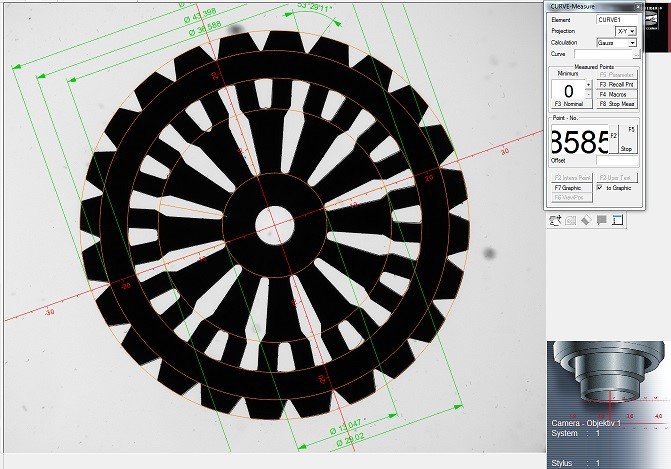

Interacting directly with the components on the workstage and automatically taking dimensional measurements as soon as the user’s hand leaves the measurement area, Saphir software can measure several identical parts or several different parts instantaneously – no fixturing required.

Components can be placed on the instrument stage in any orientation – even with the underside upwards. After initial setup, repeat measurements are carried out without even pre-loading a template - the software can recognise the shape and measure automatically - identifying a pass/fail instantaneously.

The software identifies all parts present and displays the measurements within seconds. Even when no measurement program has previously been recorded the software can recognise the contour, create a professional CAD drawing and make the alignment to perform the measurement operation.

A DXF module allows measurements to be compared with associated drawings, including tolerance bands, Go/No Go identification and DXF data export.