|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Bearing test machine |

| Home> | Efficient Maintenance | >Bearings | >Bearing test machine |

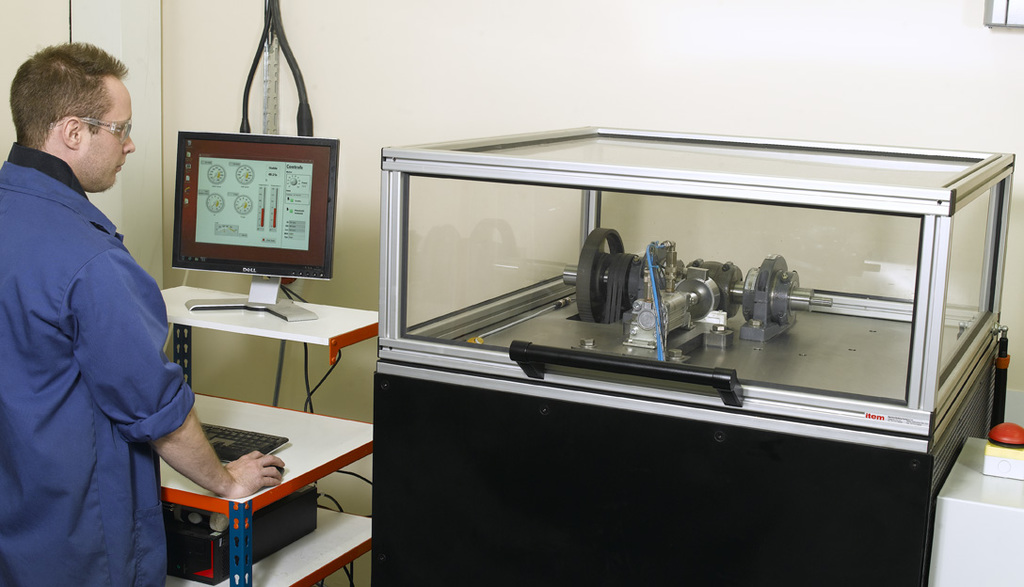

Bearing test machine

23 May 2016

Bowman International's bespoke bearing test machine provides an in-house facility that can determine bearing capabilities and provide fault analysis for plain bearings.

The development of the test machine means Bowman, which specialises in the manufacture and supply of bearings and sintered components including the Oilite and BowMet ranges, can test bearings on behalf of customers under their exact application conditions, with real time test data, remote computer operation and bearing failure onset shutdown function.

Using the new facility, Bowman can test products with dry and lubricating running and accommodate a wide range of shaft diameters. Constant data acquisition of both the test bearing temperature and torque measurement are further features.

The machine has been designed to run automatically and can sense the onset of bearing failure, which triggers an automatic stop procedure. This enables the failure mode to be analysed.

Paul Mitchell, managing director of Bowman International, said: “This facility significantly contributes to our position as plain bearings specialists. We have already used it to advise and consult on bearing specification to deliver the most suitable bearing for individual projects, even where the engineer might be unsure of the best solution and to validate material selection prior to production.

“The test machine was designed and developed in-house as part of the development of our BowMet range of rolled bearings and it has already proved invaluable, not only for providing data on our own products, but also for testing bearings on behalf of customers too.”