|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >All-in-one PLC |

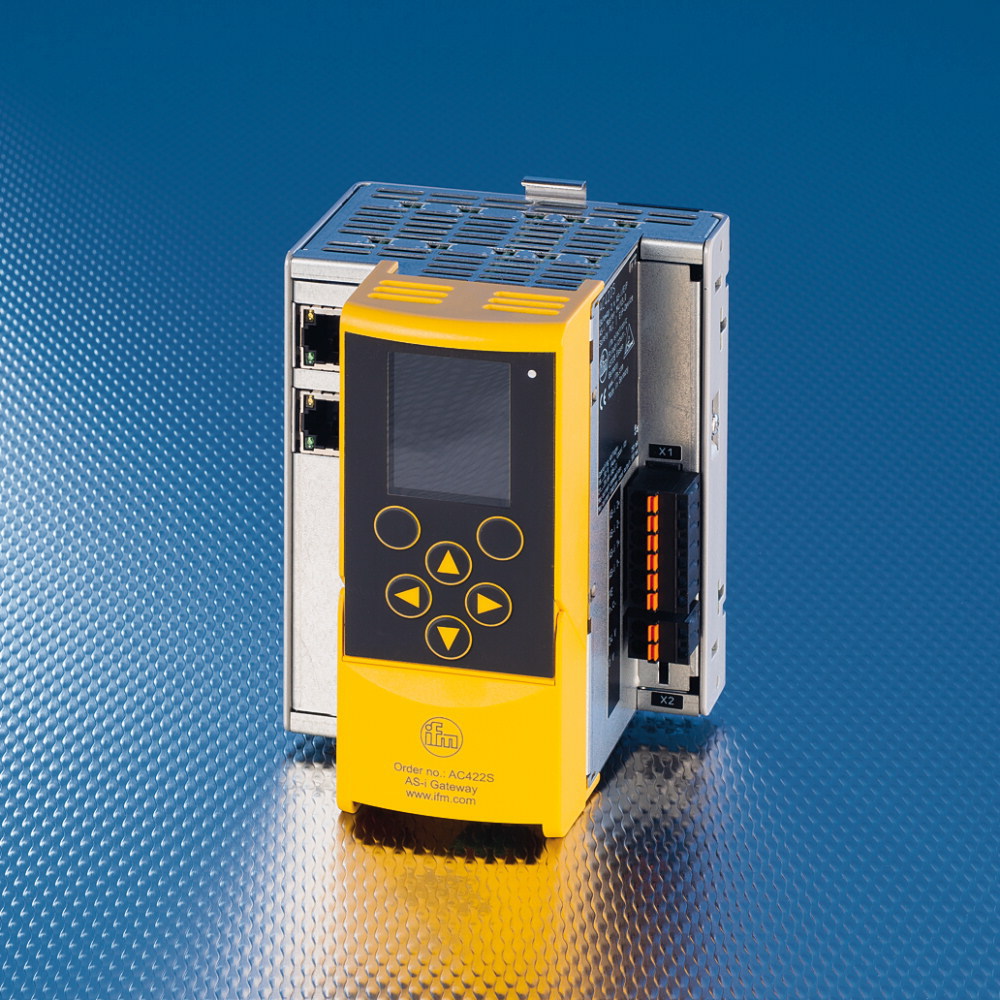

All-in-one PLC

01 August 2017

ifm’s SmartPLC combines a safety PLC and a standard PLC in one housing.

SmartPLC possesses the flexibility for a multitude of tasks, even where the safety rating reaches SIL 3 / PL e. SmartPLC is also an AS-I gateway to either Profinet or Ethernet/IP and it also acts as a data logger. It’s a visualisation system, a protocol converter and an intelligent evaluation unit in conjunction with the new ifm system solution apps.

The two integrated safety and standard PLC’s operate in tandem, using powerful processors, large memory and a multitude of supported protocols for the control of sophisticated systems .

The safety PLC is certified up to SIL3, PL e and handles eight safe local inputs and four safe local outputs. The safety PLC is programmed using CODESYS V3.

The standard PLC can also be freely programmed using CODESYS V3. Its software and hardware operates independently of the safety PLC, but it can of course communicate with it and exchange data.

SmartPLC as a gateway

Without running a programme, the SmartPLC can simply be used as a direct gateway for AS-i on one side, and Profinet or EtherNet/IP on the other. The integrated display and easy web interface display all the available status information for the user and support diagnostics in case of a fault.

SmartPLC as a data logger: the data logger function records operational system data via AS-i, EtherCAT, Modbus TCP, Profinet, EtherNet /IP, TCP/IP, UDP/IP and stored on the SD card or in the internal flash memory.

SmartPLC for process visualisation

SmartPLC features a freely programmable web visualisation based on HTML5 to provide maximum transparency. An internet browser with HTML5 capability is sufficient on the final unit. No further software is required.

As easy as using a smart phone: the SmartPLC as a platform for ifm system solutions. The tailored apps from ifm can be loaded onto the SmartPLC without programming software. The apps are loaded and configured via the integrated web interface, so all necessary settings can be carried out easily using a device with an internet browser. It’s as easy as using a smart phone and is a simple step on the road to Industry 4.0.