|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Fasteners, springs and adhesives | >High performance springs for aerospace applications |

| Home> | Handbooks | >IPE Ireland | >High performance springs for aerospace applications |

| Home> | Handbooks | >Manufacturing Matters Ireland | >High performance springs for aerospace applications |

High performance springs for aerospace applications

20 October 2017

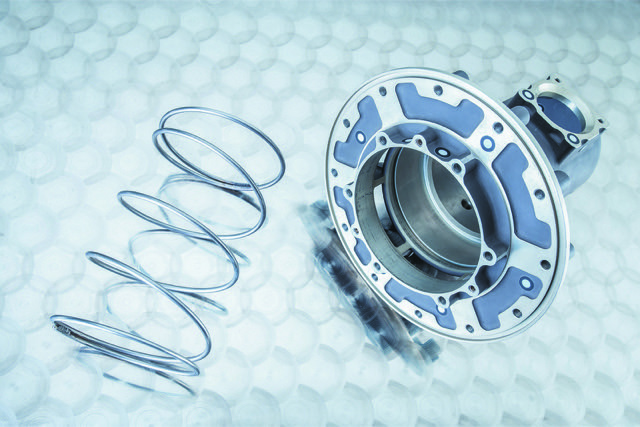

William Hughes is meeting new challenges for high performance springs in critical aerospace applications, including special requirements for materials, specifications, manufacturing tolerances, cleanliness and packaging.

For example, a spring for a safety critical aerospace non-return valve presented a challenge to William Hughes' design and production team. The application required a large spring which, as well as being manufactured in a specialist aerospace certified material – which has a high spring index making it difficult to form, the unusual specification called for one end of the spring to be fusion welded using stainless steel filler rod.

Following the welding process, end coils have to be cleaned to ensure that they are uniform with no protrusion. This is achieved using a series of grinding, polishing and deburring processes. The opposite end is then fettled on the inside to allow correct location on valve housing and both spring ends are chamfered and deburred. The spring is heat treated and passivated in William Hughes NADCAP oven process before being 100% checked for squareness and load.

Springs manufactured by William Hughes are being used in vital items of aerospace equipment including oxygen systems, access hatches and the solenoid valves used to control the hydraulic and cabin pressure systems. The company offers its customers a rapid design and prototyping service in a range of materials. This facility is particularly suited to the aerospace industry where small quantities are required for prototypes with the capability to move to volume production once a final design is agreed. Quality systems to ISO 9001:2000, ISO/TS 16949:2002 and AS9100 - the quality management system standard for aerospace companies - ensure consistency and accuracy of supply.

In addition to precision specialist springs, William Hughes can also supply bespoke bent wire forms and sub-assemblies.

- Equipped with 3D measurement scanner

- Coiled and ready for action

- More springs join range

- Specialist services

- Strong and flexible wire assembly

- Springs: Coatings and finishes

- New capacity springs into action at Wm. Hughes

- Acquisition announced

- Specialist springs support safety

- Investment in welding technology