|

Edward Lowton

Editor |

|

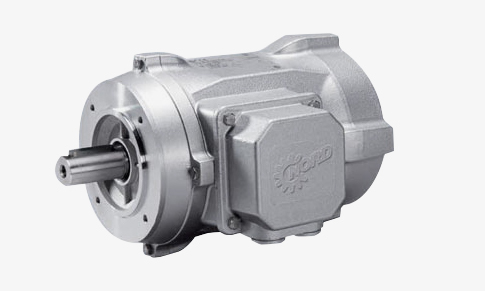

SMOOTH MOTORS

22 September 2017

These motors are excellently suited for uses with high hygienic requirements, for example in the food industry.

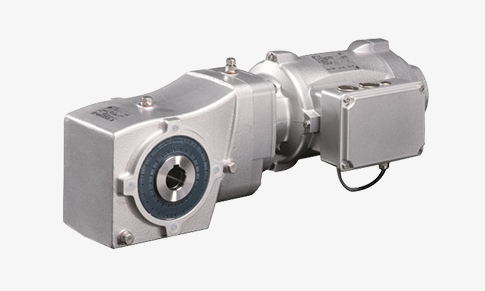

Motors with smooth surfaces are especially easy to clean thoroughly. In particular in combination with gear units with smooth surfaces (e.g. helical or bevel gear units from the NORDBLOC.1 series or SMI worm gear units) these motors are excellently suited for uses with high hygienic requirements, for example in the food industry.

NORD systems made from aluminium also comply with protection class IP69K, so that they can be cleaned with high pressure liquids. Thanks to the washdown design, these liquids drain off quickly and reliably. For optimum corrosion protection, these motors can also be equipped with an nsd tupH coating. With these properties, the lightweight metal versions are a very attractive alternative to stainless steel drive units - not only in food production and other hygienically sensitive areas, but also in harsh environments with atmospheres containing salt water.

Further practical advantages of NORD smooth motors include:

- High efficiency for a long service life, reduced operating costs and low heat dissipation (on request, surface temperatures of below +60 °C can be achieved)

- Maximum flexibility due to the NORD modular system (combination with all types of gear unit)

- Optional equipment with brakes, fans and other extras (see "Options" tab)

NORD develops its own motors and supplies them to all the major markets throughout the world. Our own developments ensure a high level of independence from external suppliers and therefore provides our customers with the decisive advantage of short and highly dependable delivery times.

For more information please Click Here

- PROFIsafe module for increased safety

- Crane drive synchronisation

- Consistent drive concept

- Simulator to take centre stage

- Drives for all crane applications

- Tailored to pump applications

- How bulk material is set in motion

- Nord Drivesystems celebrates its 35th anniversary

- NORDAC ON PURE ideal for the food and beverage industry

- Motor mounted starter for 0.25 to 7.5kW outputs

- No related articles listed