|

Edward Lowton

Editor |

|

ARTICLE

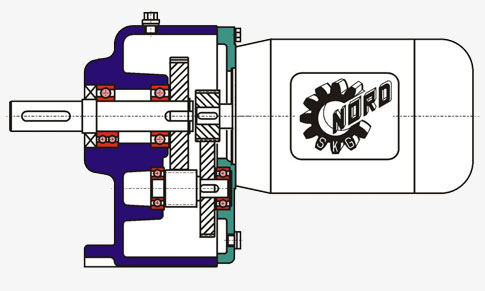

STANDARD HELICAL GEARED MOTORS

22 September 2017

Professional expertise, efficiency and high productivity are the basis for extremly short delivery times trough our worldwide service network.

STANDARD is another word for quality.

- Standard casings are purpose-designed to meet the requirements and performance level demanded today of gear boxes and geared motors.

- Series production ensures the most favourable cost-efficiency ratio.

- Professional expertise, efficiency and high productivity are the basis for extremly short delivery times trough our worldwide service network.

- The conventional line of NORD GEAR reducers has a one-piece output side housing, integral with the main housing. This permits high overhung loads since the low speed bearings are housed in a rigid chamber with no possible movement between the main housing and the bearing chamber. The gears are forged. The teeth are finished after hardening. Gearing is designed for infinite life based on DIN Standard 3990 and Niemann calculations. Fits between bores, shafts and keys are closely controlled for optimum performances.

For more information please Click Here

MORE FROM THIS COMPANY

- Same day service

- Motor catalogue details IE2 implications

- NORDAC ON PURE ideal for the food and beverage industry

- Fully functional demo

- How bulk material is set in motion

- Clean drive solutions

- New heart for inverter range

- Motor mounted starter for 0.25 to 7.5kW outputs

- Drives for all crane applications

- Nord Drivesystems at Smart Production Solutions 2024

RELATED ARTICLES

- No related articles listed

OTHER ARTICLES IN THIS SECTION