|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >PROFIsafe module for increased safety |

PROFIsafe module for increased safety

25 July 2018

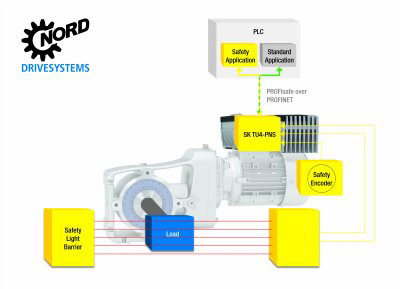

The PROFIsafe module from NORD DRIVESYSTEMS is said to fulfil the most stringent safety requirements and ensures secure communication in PROFINET environments.

PROFIsafe is a world leading technology for safety applications for production and process automation. With SIL3 and PLe (Performance Level e) Category 4, the fail-safe communication protocol fulfils the most stringent safety requirements. In combination with a safety PLC, the drive electronics reliably communicate via PROFIsafe in PROFINET.

Safe inputs and outputs, for example for emergency stop switches and light barriers, can be connected to the application with plug connectors. A rotary encoder can be connected to supervise the safe drive function.

The module is equipped with two redundantly operating microprocessors and is self-monitoring.

Various safe movement functions can be easily integrated and therefore extend the safety stop functions of the drive units: SLS (Safety Limited Speed), SSR (Safe Speed Range), SDI (Safe Direction), SOS (Safe Operation Stop) and SSM (Safe Speed Monitor). With this, the PROFIsafe module provides comprehensive safety for the reliable operation of plant and machinery.

The module is suitable both for control cabinet installation as well as decentralised installation and is available for the NORDAC LINK, NORDAC FLEX and NORDAC PRO inverter series.

- Drives for all crane applications

- Nord Drivesystems at Smart Production Solutions 2024

- Consistent drive concept

- Simulator to take centre stage

- Tailored to pump applications

- NORDAC ON PURE ideal for the food and beverage industry

- Motor catalogue details IE2 implications

- Performs without an external PLC

- New heart for inverter range

- Clean drive solutions