|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Power transmission | >Power transmission chain |

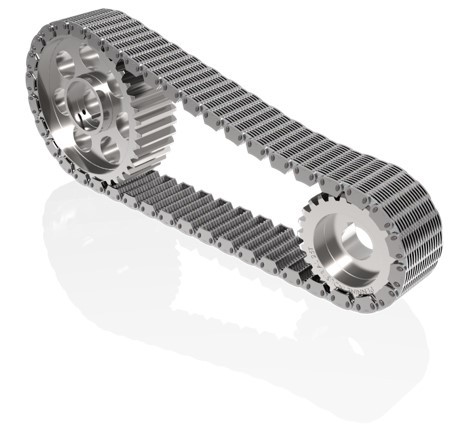

Power transmission chain

02 October 2017

Pennine Industrial manufactures inverted tooth conveyor chains for use in the material handling sectors, including for the conveying of hot glass containers, conveyors on automotive assembly lines and robotic machine tools. It has now launched a new range of Penn-Power inverted tooth power transmission chain.

Pennine’s new PP and PPV ranges use components manufactured in its assembly facility in Yorkshire and its press shop in the West Midlands; all manufacturing is undertaken in the UK and all steel used in the new range of power transmission chains is sourced from either the UK or within Europe.

The new PP range is available in both 3/8 and 1/2in pitch designs with standard widths between 3/4in (19mm) and 6in(150mm). Typical applications include chain drives with high loads and speed where space is limited.

The PPV range of chains and sprockets is said to redefine high performance for inverted tooth chains, capable of speeds in excess of 2000m/min. The chain is interchangeable with competitors' chains and, like the PP range, comes in both 3/8 and 1/2in pitch.

Both types are available in centre and side guide assemblies. All the link plates used in these chains include a number of special processes which increase the load bearing contact points and relieves material stresses giving uniformed components.

Pennine can either supply replacement chains and sprockets or design and develop complete new drives. It has its own in-house sprocket facility.