|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Water management | >Chemical-free UV disinfection |

Chemical-free UV disinfection

26 January 2018

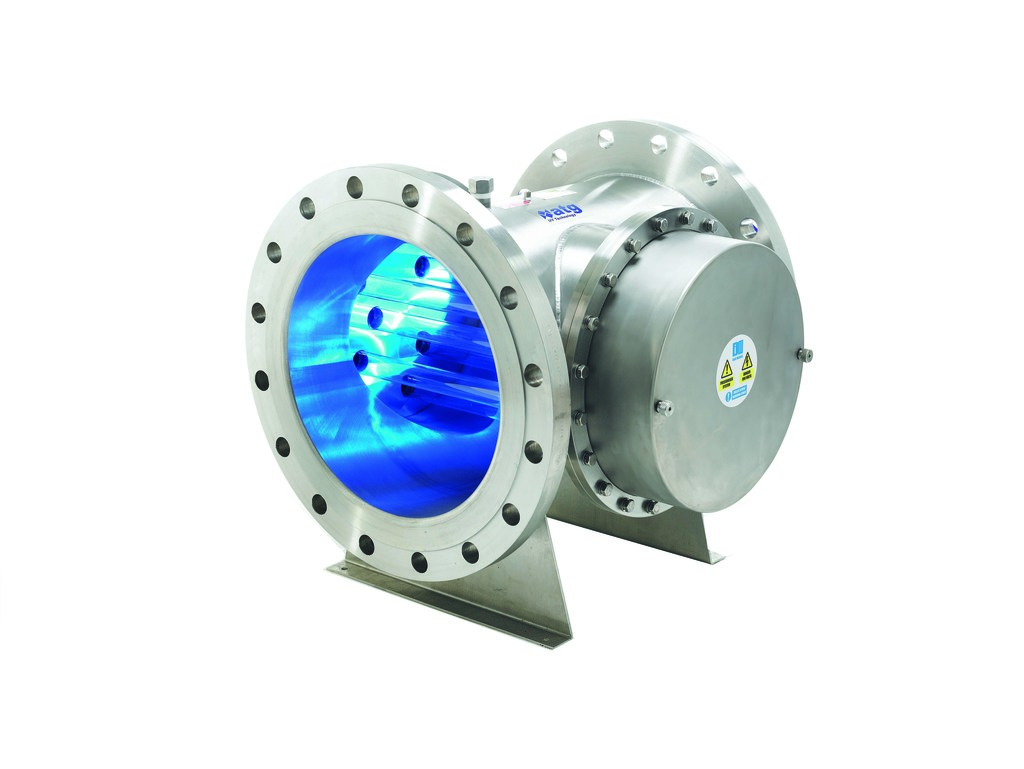

atg UV Technology, the experts in environmentally friendly, chemical-free UV disinfection, has supplied a disinfection system for Dayla’s facility at Ross-on-Wye.

Dayla is a specialist bag-in-box packaging company for a number of large and small brands. It has a daily output of 15,000 litres of juice products and 37,000 litres syrup products for clients including Barr Soft Drinks, Coca-Cola and Sunkist. Traditional water disinfection processes in the soft drinks industry use oxidising biocides like sodium hypochlorite, chlorine dioxide or ozone. However, in the presence of organic matter, even at low concentrations, chlorine based chemicals can produce a range of potentially carcinogenic by-products including trihalomethanes (THMs), haloacetic acids (HAAs) and nitrosodimethylamine (NDMA), whilst ozone can generate bromates from bromide in the raw water. All of these by-products will pass through reverse osmosis membranes into the product water.

“All the water we use is purified by reverse osmosis”, says Dayla’s Technical Manager, Darren Atkins, “so we opted for UV to avoid any of the problems associated with disinfection by-products.” atg’s solution was a SX-225-8 UV system capable of delivering a UV Dose of 120mJ/m2 into a flow of up to 20 m3/hr of purified water with UV Transmittance 98%, ensuring a 4-log inactivation of cryptosporidium and adenoviruses and 5-log (99.999%) reduction in viable bacteria. The ultra-efficient 800 Watt Amalgam UV lamps offer a range of benefits including guaranteed lamp life of 16,000 hours, optimized UV reactor design for reduced headloss and significant capital and operating cost savings by comparison with conventional systems.