|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Achieving functional safety in automated production |

Achieving functional safety in automated production

02 March 2018

The 2018 MACH Show will be the platform for demonstrating SICK’s UK SafetyIQ concept, the company’s universal approach to ensuring safe, compliant personnel protection without compromising on machine availability, efficiency and productivity.

SICK’s machinery safety experts will be on hand on to discuss SafetyIQ, a full suite of safety products, services and systems underpinned by networking and integration that enables customers to achieve Industry 4.0-ready functional safety in automated production.

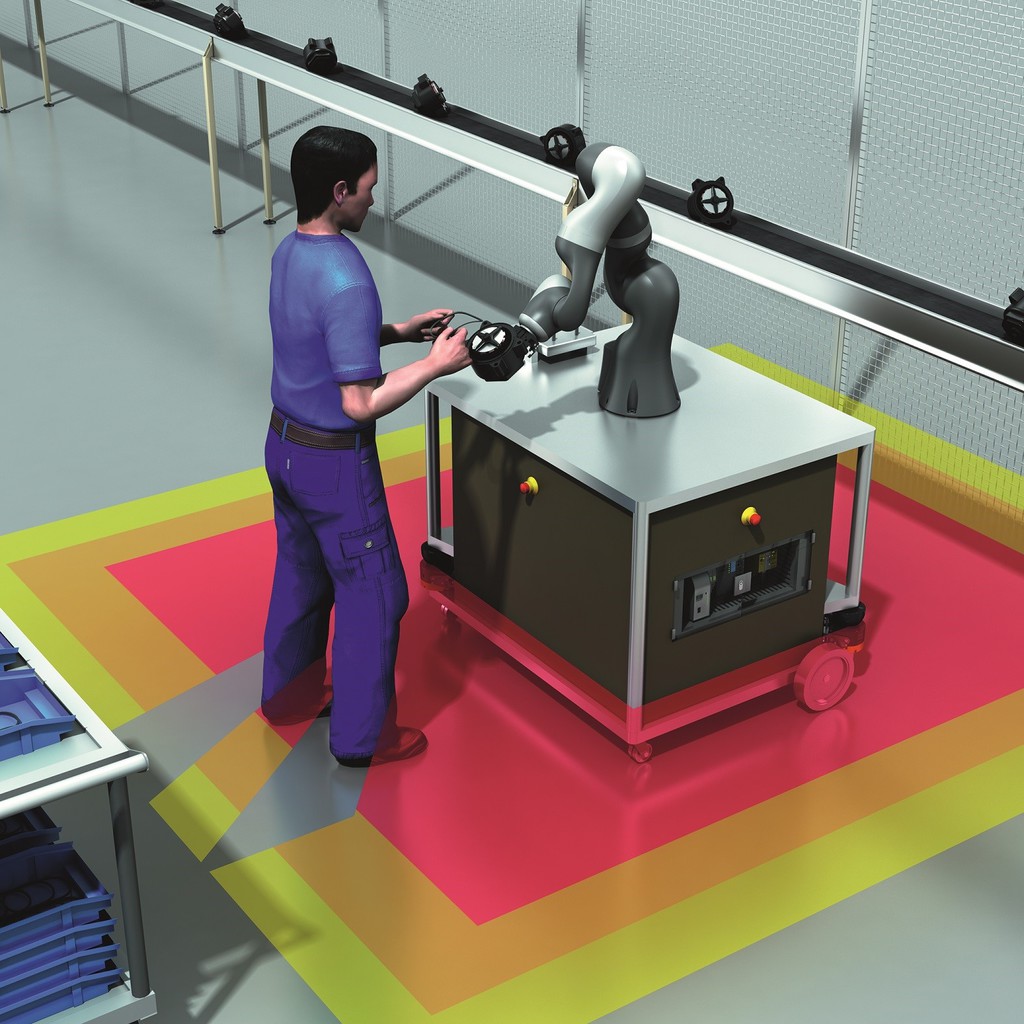

Safe human-machine collaboration will take centre stage on SICK’s stand with an Industry 4.0 robot exhibit. Visitors will be able to personally interact with the robot, demonstrating a range of SICK solutions including robot guidance, RFID and 2D LiDAR scanning technologies as well as showing how SICK’s safety light curtain and laser scanning technologies can be successfully integrated with the SICK FlexiSoft safety controller.

Stand H18-421

- High speed and read reliability

- Light curtain alternative

- Sensing a clear solution

- SICK switches up cylindrical inductive safety sensor offering

- Light curtain

- All-Purpose Proximity Sensing from SICK in One Second Flat

- Contour-based localisation system

- Optical level switch

- IO-Link compatibility added to absolute encoders

- Digitalisation solves a daily headache for IKO