|

Edward Lowton

Editor |

|

Cleaning up with a new 'chip fan'

25 April 2018

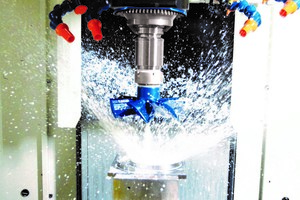

For machining applications that generate significant levels of swarf, Industrial Tooling Corporation (ITC) has now introduced the new Chip Fan from BIG KAISER. The tool is said to offer a fast and safe method for removing chips and coolant from the work envelope without stopping production.

The blades of the Chip Fan are turned by the spindle on the machine tool. With a finely balanced design, the device operates at spindle speeds to 12,000rpm to provide powerful, high-volume air cleaning. The company says this is efficiently achieved without any of the dripping coolant and flying chip issues that are associated with conventional air hose blasts.

To ensure its long life and durability, the BIG KAISER Chip Fan is manufactured from a high-strength anodised aluminium. Furthermore, the chip fan comes with a pre-drilled hole that allows through coolant spindles to distribute coolant through the centre of the fan to rinse off tables, fixtures and workpieces. Following this cycle, the fan runs at a high speed to remove any remaining chips or coolant, thus performing two cleaning operations in a single step.

ITC says that, ideally, the Chip Fan should be programmed into the machining cycle to minimise spindle downtime and maximise operator efficiency. Safety is also improved as all the swarf and coolant is neatly contained within the machining enclosure and kept off the shop floor.

Giampaolo Roccatello, VP for sales at BIG KAISER, says: “Keeping production equipment clean significantly improves reliability and quality while also ensuring a quieter working environment. Our new Chip Fan means chips and coolant can be quickly and easily removed without any interruption to production. This maximises productivity and prevents unpleasant costly delays.”

- ITC introduce carbide boring bar from BIG KAISER

- ‘Clearcut’ Winner For Tackling ACM Delamination Challenges

- 2023 product catalogue available from ITC

- Latest back chamfering series

- ITC to present latest BIG KAISER innovations at MACH

- Tightening fixture for collet chucks with an integrated torque indicator

- New line has a ball with steel

- Getting a grip on precision boring

- ITC simplifies advanced micro-machining

- Howells on track to success with ITC

- No related articles listed