|

Edward Lowton

Editor |

|

Tapes designed for electric vehicles

12 July 2018

Adhesive tapes offer an alternative to traditional mechanical fastening methods and Techsil believes they have a role to play in the electric vehicle (EV) manufacturing sector. Options range from structural bonding tapes and anti-noise tapes to prevent rattles and squeaks through to closed cell foam tapes to provide waterproof seals.

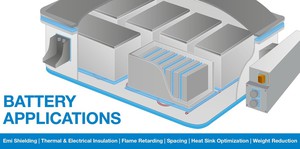

Techsil has introduced a specialist adhesive tapes range specifically for EV battery applications. These tapes offer properties such as EMI shielding, thermal and electrical insulation, flame retarding and heat sink optimisation. The range is manufactured by ITW Stokis Tapes and includes:

StokTherm – thermally conductive interface tapes that can give electrical insulation or act as a cooling bridge to the cooling unit.

ITW Formex – tapes that offer mechanical protection, electrical insulation and EMI shielding to battery covers and busbars and can be used as a cell separator.

StokSeal – PU and silicone adhesive foam pads that are used for cushioning, thermal insulation, sealing of housings and connectors against water ingress and as compression pads giving compensation for cell expansion.

In partnership with ITW Stokvis, Techsil can also offer Laminating and Die-Cut services.

- Laminating - to make proprietary products self-adhesive or laminating different tapes onto each other creating unique easy to apply materials.

- Die-Cut Services – to engineer new shapes and new combinations of materials to reduce application time and find a creative fixing solution.

- RTV silicone adhesives achieve Airbus Industrial Qualification

- Electronics adhesives cure with UV, visible light or moisture

- Meter measures UV light in curing systems

- Hybrid structural bonders

- Jettable conductive adhesives

- Beating the heat with silicone adhesives

- UV adhesive for hard-to-bond plastics

- Technical sales manager joins the team

- Cures with UV & visible light

- Low odour methyl acrylate adhesive