|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Bearings: The Final Frontier |

Bearings: The Final Frontier

27 May 2022

ONE OF the most critical bearing applications in the aerospace industry is machinery which requires motion control on manned space flight missions, with this area currently experiencing significant investment and growth.

Despite all the global challenges and uncertainties, the UK and European space sector is thriving, a good example of which is the Oxford Space Cluster. This facility is acknowledged as the UK’s leading space technology gateway with a global reputation for innovation, from space science research to ground based commercial solutions. Today, the Harwell Space Cluster forms an integral part of the UK’s space sector and has grown into a dynamic and enterprising ecosystem comprising over 100 organisations, employing 1400 people and contributing £5.7bn to UK GDP.

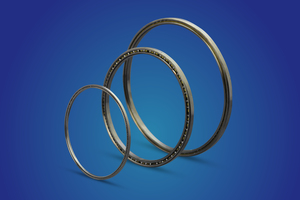

Located in close proximity to the Harwell site is Oxfordshire-based precision bearing specialist Carter Manufacturing. The company is the European master distributor for US-based Napoleon Bearings. With over 25 years of service and excellence in the aerospace manufacturing industry, Napoleon offers customers the crucial benefit of 'Space Heritage' a status that is critical for suppliers to the space industry. This is underlined by the fact that Napoleon has supported both NASA missions in the USA and also projects initiated by the European ESA by supplying components for life-critical space applications.

Thanks to its representation of Napoleon Bearings - one of the manufacturers of choice for the most critical bearing applications - Carter can pass on unrivalled expertise gained from manned USA space flight missions, to similar projects for their UK and European customers. As a result, from low earth orbit to Mars exploration and beyond, outer space approved bearings, along with other key components, are helping customers to explore and conquer new frontiers with confidence.

Supporting space exploration

In addition to supplying the highest specification bearings to UK and European customers, Carter has also supplied components such as Cam Followers for the Mars Rover project, Rod Ends and aerospace bearing tools for the Thales satellite project along with bearings for deployable antennas for other space exploration projects.

Other specific aerospace applications in which Carter has supplied products includes; launch vehicle satellites, LOX turbo pumps and circulators, liquid methane pumps, reaction wheels, solar array gear box mechanisms, door latches and other space components.

Providing worldwide customers peace of mind, Carter is accredited to ISO9001, incorporating the requirements of AS9120 with flow down from AS9100, while bearings can include AS9102 Aerospace First Article Inspection. This includes reports for traceability of all raw materials and special processes along with full dimensional analysis.

Additionally, Carter also possesses extensive knowledge of the quality and testing requirements which are required to validate a new bearing design or other components.

Carter’s engineers utilise SolidWorks to design custom bearings tailored to each mission, while the company's proprietary bearing application software determines theoretical bearing performance. To complete the package, other software allows the firm to provide detailed reports to better inform customers and validate critical design decisions. Carter can also provide further technical assistance such as FEA analysis and this level of support, combined with its unique understanding of how to interpret this data, optimises mechanical performance.