|

Edward Lowton

Editor |

|

| Home> | Handbooks | >Manufacturing Matters Ireland | >Mixers for chemical and thermal processing |

| Home> | Plant, Process & Control | >Process equipment | >Mixers for chemical and thermal processing |

Mixers for chemical and thermal processing

18 March 2020

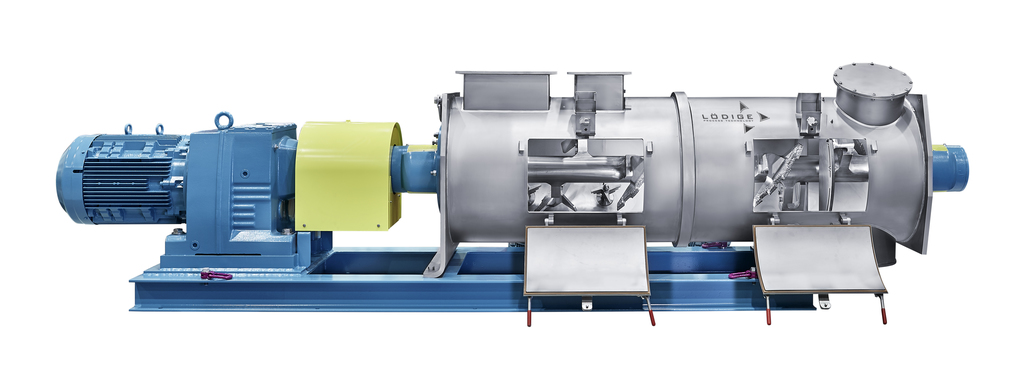

Lödige Process Technology's Ploughshare mixer is an example of its durable process engineering systems for mechanical, chemical and thermal processing of sludges, sewage sludges, ashes, dusts and other waste materials.

Ploughshare mixers are based on the mechanically-generated fluidised bed process patented by Lödige. This process involves Ploughshare shovels rotating close to the walls of a horizontal, cylindrical drum. Ploughshare mixers are available for both batch mode and continuous processes.

The continuous Ploughshare mixers in the KM series are particularly suitable for environmental engineering applications. This low-maintenance mixer model is intended for processing powders, fibrous or granular solids, but also fluids and pastes. The continuous mixer even performs granulating processes with minimum retention times. It is characterised by excellent repeatability, maximum homogeneity of the final product, short retention times and great economic efficiency.

The sophisticated mixer concept also includes universal applicability of the machine. Beyond processing of dry, powdered, granular or fibrous solids, it can also be equipped for numerous other mixing tasks. Adding fluids to moisten product components is just as possible as processing pastes and fluids. Moreover, installation of choppers in the mixing drum permits breaking up of agglomerated material as well as systematic granulation during the mixing process.

A heated and cooled drum, head pieces and shaft are also among the available equipment options. If the machine is subject to particular wear, extremely wear-proof surfaces, high tensile structural steel materials, stainless steel and special materials increase the high availability of the Ploughshare mixer even further. A broad range of different mixer sizes allows for even more versatility. The smallest model with a drum volume of 5 litres boasts a feed rate of 0.25m3/h based on retention time and degree of filling. The feed rate of the largest model to date with a 57,000L drum volume is 1300 t/h.