|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Power transmission | >Flexible drive shaft |

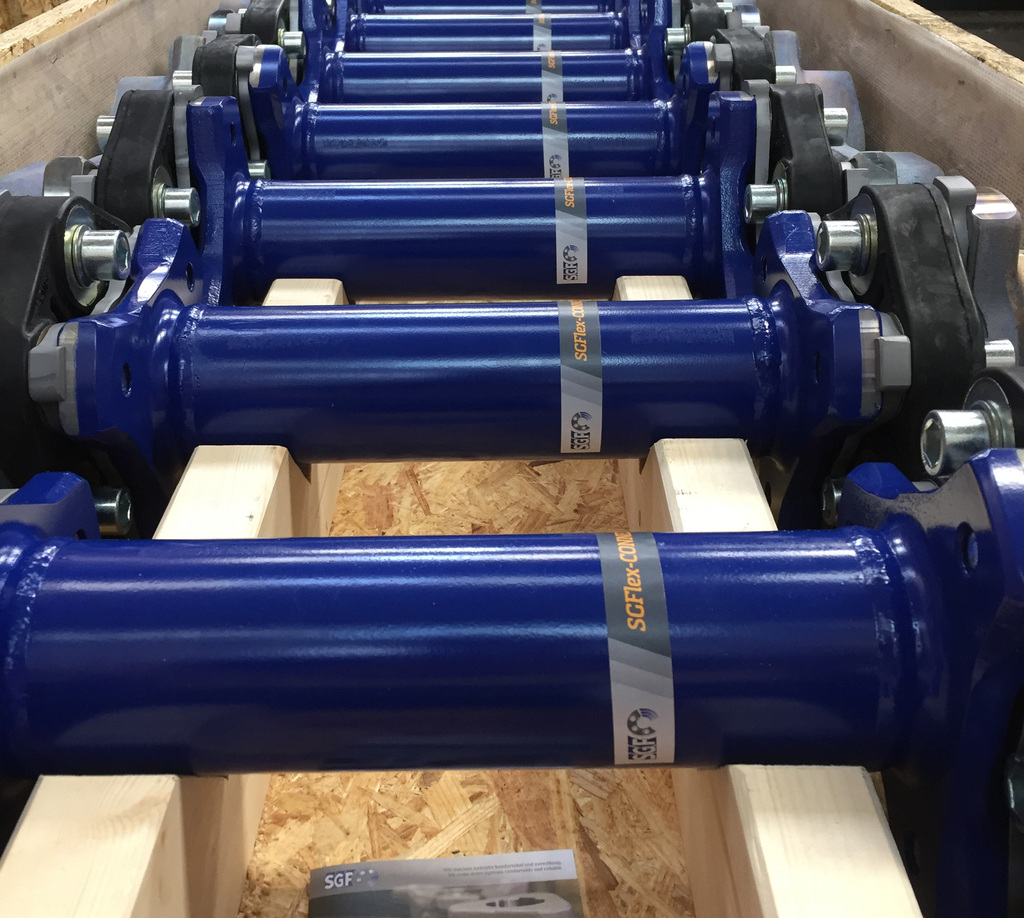

Flexible drive shaft

04 February 2019

SGF's first flexible drive shaft, the SGFlex-3FD-CONNECT, is said to combine the advantages of common drive shafts with the advantages of flexible couplings, providing a vibration-damping alternative to drive shafts with universal joints.

The shafts are suitable for main drives in agro-technology and construction machinery, as well as for use in test benches, cooling towers and steelworks. Vibrating conveyor screens and stone forming machines are also said to benefit from the maintenance-free, flexible shafts, the compensation of radial, axial and angular misalignment, as well as the damping of high torque peaks thanks to Tenpu fibre technology.

The shafts in the SGFlex-3FD-CONNECT series operate at a zero-degree bending angle, which SGF says is usually not possible in constructions with synchronous or universal joints. The new flexible drive shafts are available in six standard sizes with a nominal torque from 100 to 3200Nm. Maximum shaft diameter is 127mm; the largest available standardised shaft distance is 2000mm.

Optionally, SGF manufactures products in the SGFlex-3FD-CONNECT series with electrical insulation or with a CFRP shaft for lightweight and high-rev applications. For use in harsh industrial environments, the company can produce variants that withstand aggressive media or temperatures higher than 120°C.

SGF has developed a new centering system specifically for the SGFlex-3FD-CONNECT series, which, among other things, enables the intermediate shaft to run smoothly. Due to the special system, the flexible couplings can be mounted together with the centering without displacing the drive and driven aggregates.

With this flexible drive shaft, torque is transmitted almost exclusively via vulcanised cord inlays due to the SGF tension-force-principle. The patented Tenpu fibre technology ensures high power density, elasticity and good damping behaviour. Load peaks and vibrations therefore are said to have less of an effect on the aggregates in the powertrain, which benefits their service life.