|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine Shop Equipment | >Friction joints for benchtop assembly tasks |

Friction joints for benchtop assembly tasks

06 November 2019

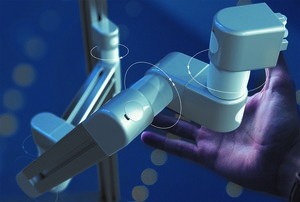

The latest friction joints from FATH Components are designed for use in a variety of benchtop assembly applications.

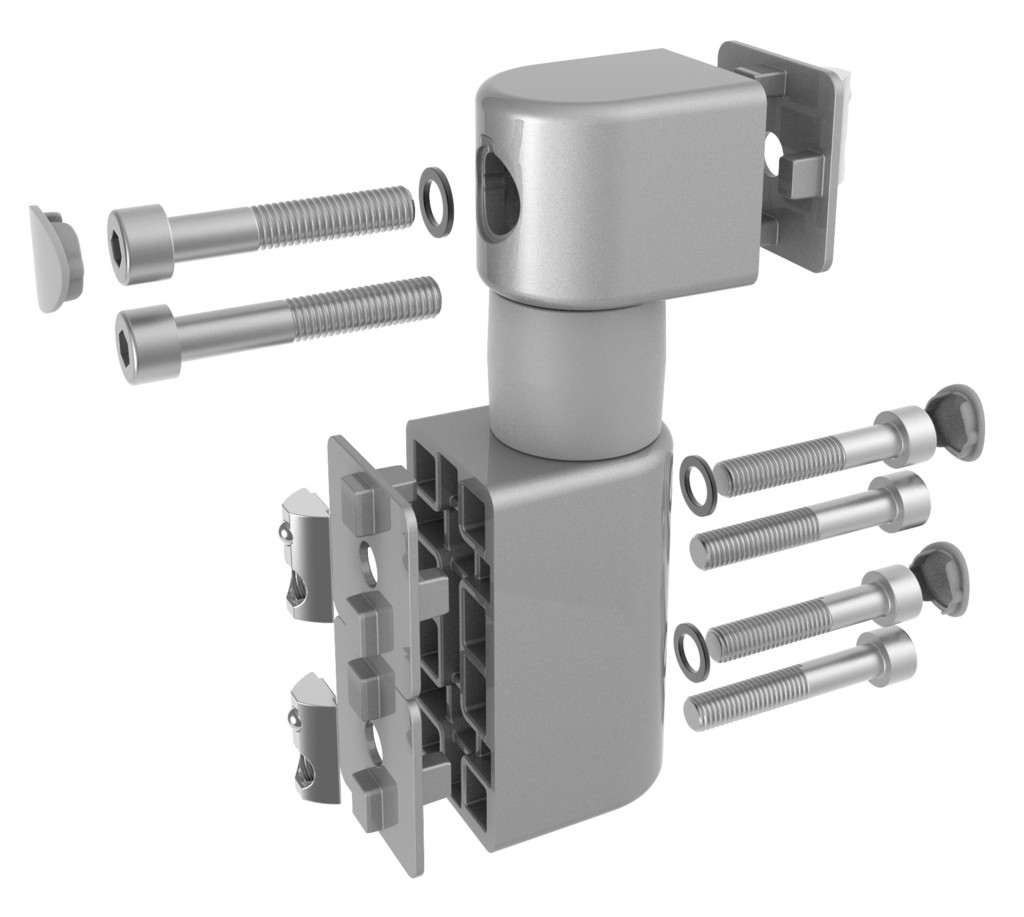

The Aldershot-based supplier is part of the German FATH Group of companies and has launched three new models of friction joint, all of which are available now ex-stock, with six different versions of each to choose from.

The 140L and 180L friction joints offer operating torques from 0.5nm, through 3, 6, 9, 12 and 15nm, thus allowing users plenty of choice to obtain an optimum match between the operating arm and the work in hand. Handily, the new FATH range also includes a larger, heavier duty 180H friction joint for users with bigger masses to move.

FATH states because the operating arm can pivot freely in the vertical plane without fear of it dropping, (even with repeated, high cycle use), its new friction joints allow users to further improve productivity on the factory floor.

Using standard FATH stock swivel arms and associated components, the new friction joints can be mounted direct onto profiles lengthways, crossways or end-on. For the easiest and speediest possible mounting process, the fasteners which attach the new friction joints are all located outboard and are inserted inwards facing. Plastic caps are supplied with each unit to ensure that a smooth, clean look is effected by covering the fastener heads following assembly.

FATH’s UK managing director, David Hayes, observes: “The introduction of this new range of premium-quality friction joints is a useful addition to a substantial ex-stock product portfolio supplied from our Aldershot HQ. The new friction joints have been introduced to meet customer demands for reliable, durable and easy-to-use equipment that enhances both the operator experience and productivity levels on all types of workstations. We now offer more than 23,000 different components for machine builders and OEMs to choose from, and have experienced staff here to assist customers by providing expert advice and guidance when required”.

- Driving additive manufacturing forward

- Protecting workers from fumes and dust

- Mobile laser hardening robot helps boost efficiency

- Reusable industrial clamp

- Devices for TIG welding added

- Daylight quality lighting

- Thin film conversion coatings

- 3D printing used for Kew's dragons

- Tool order

- Customised blast cabinet upgrades armature repair