|

09 November 2021

|

|

ENGINEERING TECHNOLOGY Group has introduced the VMC650B, the smallest in the Vulcan line of CNC machining centres.

[Read More]

|

|

|

|

15 October 2021

|

|

A LEADING UK manufacturer of downdraught benches, Airbench has unveiled an ATEX-rated version of its VertEx cross-draught system.

[Read More]

|

|

|

|

24 September 2021

|

|

WILLIAM HUGHES Group has announced that it has perfected a method of composing and forming complex automotive electric vehicle (EV) bus bar geometries out of pre-coated copper stock and says it can do so in such a way that the insulation/protective cover remains completely viable along the length of the bar.

[Read More]

|

|

|

|

01 June 2021

|

|

A LEADING manufacturer of downdraught benches and cross-draught systems, AirBench has announced the release of VertEx VX, an ATEX-rated version of its VertEx cross-draught system.

[Read More]

|

|

|

|

29 March 2021

|

|

CLEAR PRESSURE tanks from SR-TEK help reduce research and development time by allowing engineers and scientists to observe reactions and make changes in real-time.

[Read More]

|

|

|

|

03 February 2021

|

|

ELESA has formed a partnership with Misati, whose high-performance pneumatic clamps offer exceptional clamping action in work holding, or transport of assemblies in manufacturing operations.

[Read More]

|

|

|

|

30 November 2020

|

|

ENGIS SUPERABRASIVE single-pass bore finishing offers high precision tolerances in a large scale production environment. The single pass process uses a combination of superabrasive-plated tools, pre-set to exact dimensions, which are passed through the bore, rotating as they complete the honing operation.

[Read More]

|

|

|

|

30 September 2020

|

|

A NEW downflow workstation from AirBench is designed for light duty fume extraction applications.

[Read More]

|

|

|

|

30 September 2020

|

|

WILLIAM HUGHES has come to the aid of an automotive tier-one seat manufacturer, a mission made possible by the company’s broad skill set and advanced capabilities in the world of complex wire forms.

[Read More]

|

|

|

|

30 July 2020

|

|

AirBench has announced the release of its new DF range of down flow workstations for fume control.

[Read More]

|

|

|

|

27 July 2020

|

|

New drive controllers and motor filters for high frequency (HF) applications from KEB Automation are helping customers develop highly efficient machine concepts for turbo blowers and CNC machine tool spindles. The objective is to increase performance and protect the motor windings at output frequencies up to 2000Hz

[Read More]

|

|

|

|

17 June 2020

|

|

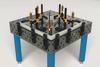

A wide range of Siegmund tables and clamping systems are available in the UK from distributor, Surface Technology Products (Surtech).

[Read More]

|

|

|

|

12 June 2020

|

|

Siegmund modular tables and tools are designed for forming, clamping, assembly and welding. They are flexible, hard wearing and indestructible, according to Surface Technology Products (Surtech).

[Read More]

|

|

|

|

18 June 2020

|

|

TLM Laser has announced a partnership agreement with BODOR Laser and will distribute the company’s range of high precision metal laser cutting systems within the UK and Ireland.

[Read More]

|

|

|

|

15 March 2020

|

|

AirBench BD is a self-contained blowdown station for the removal of coolant and swarf from machined parts. An operator can simply place parts in the cabinet, lower the screen and use the integral blow gun to clean parts using factory compressed air.

[Read More]

|

|

|

|

16 March 2020

|

|

AirBench has announced an upgraded range of AOF oil mist filters for extraction of oil mist and smoke from machining applications.

[Read More]

|

|

|

|

16 March 2020

|

|

A new white paper from Kistler shows how injection moulders can use the company’s ComoNeo monitoring system to minimise and, in many cases, eliminate rejects.

[Read More]

|

|

|

|

25 February 2020

|

|

AirBench BD is a self-contained blowdown station for the removal of coolant and swarf from machined parts.

[Read More]

|

|

|

|

06 December 2019

|

|

Guhring has added the RT100XF drilling line to its holemaking portfolio.

[Read More]

|

|

|

|

06 December 2019

|

|

Surtech has introduced new polishing and grinding machines which meet the latest health and safety requirements.

[Read More]

|

|

|