|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Grinding and abrasives | >New severe service ball valve diamond lapping gel |

| Home> | Handbooks | >Manufacturing Matters Ireland | >New severe service ball valve diamond lapping gel |

| Home> | Plant, Process & Control | >Valves and actuators | >New severe service ball valve diamond lapping gel |

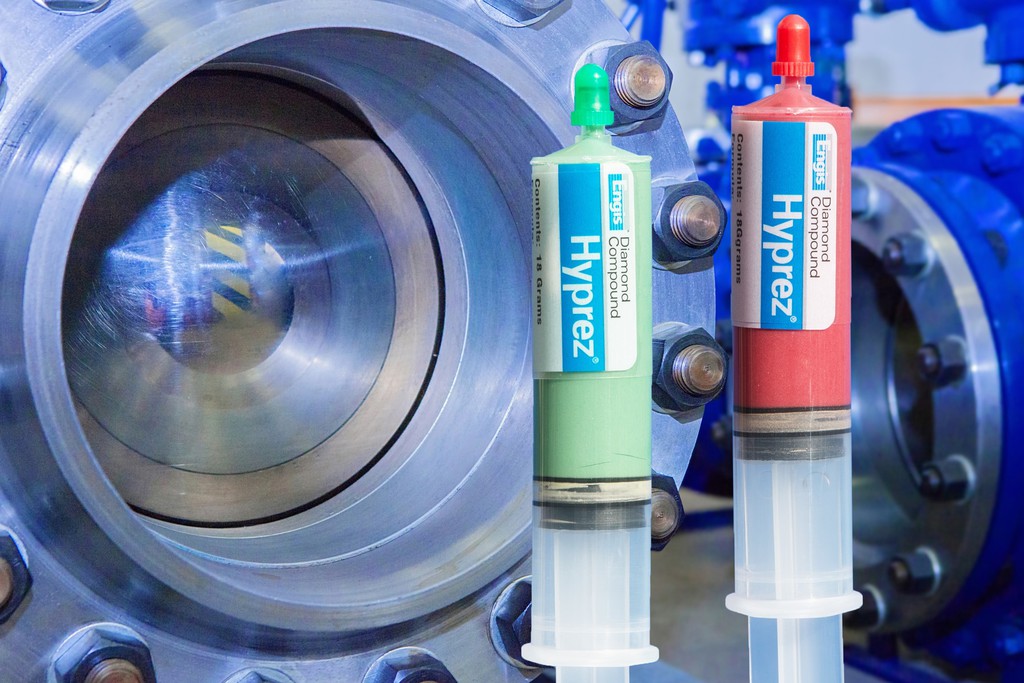

New severe service ball valve diamond lapping gel

16 March 2020

Engis has worked with ball valve manufacturers to develop a lapping gel for severe service ball valve lapping applications, such as oil and gas production and petro-chemical refining.

Benefits of the Engis LD diamond lapping gel are said to include longer cycle-time per application, (approximately twice the length of some compounds) resulting in less downtime and faster lap rates, which can reduce overall lapping time by up to 30-40%.

Less pressure is required using the LD Gel, reducing scratching and operator fatigue, resulting in reduced scrappage, while test stand failures are significantly reduced – to near zero in some instances.

Engis lapping gels contain specially controlled diamond particles micronized in Engis laboratories, whereas some conventional lapping compounds often incorporate rogue abrasive particles resulting in surface scratches, compromising the zero-leak goal.

Engis LD Gel is available in 18g or 100g syringes in particle sizes ranging from 60 microns down to 1 microns.

- Showing superabrasives solutions

- Surface engineering solutions

- Lapping solutions for valve manufacturers

- Vitrified diamond and CBN wheels

- Diamond lapping gel for tough tasks

- Diamond lapping gel for severe service ball valves

- Lapping solutions for valve manufacturers

- Lapping solutions for valve manufacturers

- Single pass bore finishing