|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Keeping warehouse operations in line |

Keeping warehouse operations in line

14 March 2023

One easy-to-implement method of minimise hazards and maximise efficiency in warehouses is utilising paints and coatings to improve both warehouse safety and productivity, says Scott Saunders

ONE OF the biggest obstacles in warehouse management is balancing speed with accuracy. Warehouses are typically very fast-paced workplaces and employees are often battling to meet targets. However, if they are achieving speed at the cost of accuracy, employees could easily get hurt or damage stock and equipment.

Having to juggle so many factors can be a challenge for warehouse managers. But a good starting point is to ensure the effective use of space, which is vital to minimise hazards and maximise productivity. One easy-to-implement method is using area and line marking to zone a facility and streamline operations.

Minimising hazards

Warehouse managers have a lot to think about when responsible for a site, but health and safety should always be at the top of the list.

HSE statistics found that 1 in 10 non-fatal workplace injuries in 2021/2022 were caused by workers being struck by a moving object, for example a pallet truck, trolley or piece of automated machinery. Sometimes the cause of the strike is as simple as someone not looking where they were going or crashing into some racking because they did not have full visibility when pushing an overloaded trolley.

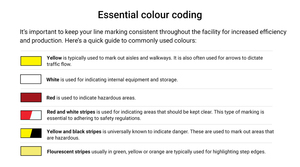

One of the best methods to address such common warehouse hazards is to implement clear line marking with coloured paint and symbols. Introducing demarcated routes can help to separate pedestrians from potential hazards, maintain safety zones, highlight emergency exits and ensure storage areas are appropriately labelled. As a result, workers are less likely to encounter hazards, especially for visitors who may be less familiar with a space.

For one-off temporary layouts or areas that are frequently redesigned, safety and clarity is still essential but paint may be less appropriate. In these instances, tape is the perfect alternative as it is quick and easy to change in line with a new configuration.

Maximising productivity

Partitioning areas with clear line marking is also vital to ensure the smooth running of a facility.

Zoning a warehouse with colour helps to keep vast spaces clean and tidy. This is crucial for productivity because a well-maintained space enables employees to quickly and easily spot where stock levels might be low, and find out where equipment, or products, are stored.

This is particularly beneficial for visitors or new starters who are unfamiliar with the layout of a warehouse. Mapping out one-way traffic, production areas, and storage areas with appropriate line markings, employees will benefit from an easy-to-follow layout. This not only minimises stress, but can also significantly increase speed of service, giving workers more capacity to meet demand.

Furthermore, using colour and design to zone certain areas can improve the look and feel of the working environment. This can have a big impact on employee satisfaction and retainment, especially within large warehouses with minimal windows that struggle to keep a space feeling light and aesthetically engaging. High-gloss finishes are perfect for reflecting light, and can be particularly effective in this type of space.

Line marking, coloured paint and symbols are a simple but effective way to highlight hazards, signpost stock and improve the overall aesthetic of a warehouse. All of which can positively impact productivity, employee wellbeing and business profitability.

Scott Saunders is technical service manager at Watco

For more information:

Tel: 01483 418 418