|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Electrical components | >The digitalisation trends impacting the use of input/output modules |

The digitalisation trends impacting the use of input/output modules

25 September 2025

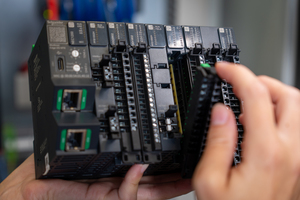

A NEW breed of I/O module is being introduced to meet the fast-growing need for decentralised data processing. Schneider Electric’s Dave Sutton, product marketing manager for industrial automation, explores how businesses across industrial applications from simple to the most demanding can improve performance at the I/O level.

As industry adopts distributed control systems, there is a need for decentralised input/output (I/O) devices to process data closer to the source, providing a way for businesses to make informed decisions at the machine level. At the same time businesses are deploying more IoT devices, which is furthering the need for I/O modules to translate data between machines and their control systems. New generation I/O systems deliver greater scalability and flexibility. In turn industrial businesses can adapt to market needs, simplify digital transformation, and save on valuable engineering time.

OEMs, system integrators, and end users should make the I/O level work for them, with adoption of a cutting edge I/O solution holding the key to delivering a reduction in total cost of ownership and robust cybersecurity. Integrated diagnostics, as well as simpler design and wiring will cut down complexity from pre-sales all the way to operation. Advancing at the I/O level empowers businesses to keep up with rapidly changing consumer and market trends, quickly introducing new assets or adapting processes without barriers. Intelligent I/O solutions can also streamline cybersecurity concerns, playing a vital role in the protection of the network as the facilitator of data transfer. Each of these capabilities offers value to entire manufacturing supply chain.

Creating a strong foundation

A new generation of I/O modules has been developed to play a significant role in the digital transformation of industry, as businesses can only achieve the benefits of digitalisation when they can rely on secure, scalable and flexible data transfer. The key is to adopt new I/O solutions that are capable of seamless integration of data across assets and devices regardless of what is already installed. Seamless integration ensures that even facilities with legacy assets remaining in operation can realise the efficiency improving potential through analytics.

Communication and future-proofing

Compatibility with open industry standard Ethernet protocols such as Ethernet/IP, Modbus TCP and OPC-UA provides interoperability and future-proofing as it lays the foundation for a new generation of connected products.

24/7 operations

The latest type of I/O solution can also cut downtime and its associated costs due to hot swap capabilities. This means that plant managers, maintenance teams, and OT professionals can react to issues by replacing a module (or slice) immediately, therefore minimising the impact of unforeseen maintenance and ensuring availability, whether an application is simple or demanding.

Data Continuity

That same modular design also provides flexibility to add new machines and adapt processes without extensive reengineering. These I/O capabilities deliver scalability for businesses of all shapes and sizes, ensuring the solution can not only grow with a business but also provide flexibility for the future.

As industrial manufacturers adapt their hardware and software to take advantage of digital transformation, they need I/O technology that is flexible, scalable and protects the valuable flow of data.

The latest I/O modules, such as Schneider Electric’s Modicon Edge I/O Network Terminal Slice (NTS), represent a smart solution that prepares industrial operations for the data-driven future. OEMs, systems integrators, and end users can meet the needs of any application within a single I/O family. Find out more here.

- Collaborative approach

- New Schneider Electric Director of Operations, Services and Projects in Ireland

- New drive for the smart machine era

- Valve selection: Back to basics

- Driving forward a holistic approach

- Schneider & Cisco partner to bridge OT/IT in building management systems

- A new era of industrial computing

- AI – changing industry as we know it

- Quality matters

- Energy bills: Greater visibility