|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Fit for motion monitoring |

Fit for motion monitoring

31 January 2019

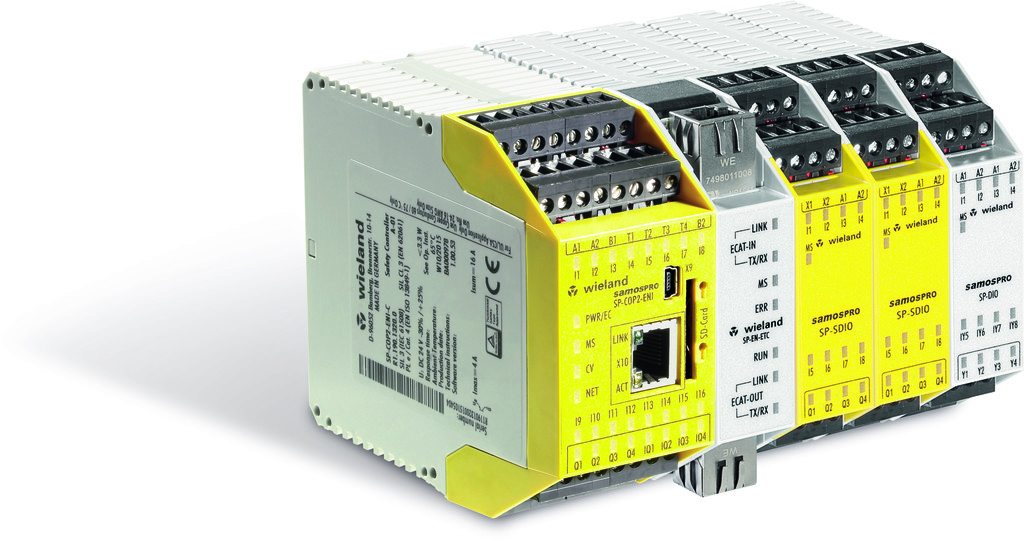

The progressively dynamic nature of today's processes and production sequences mean tougher requirements to ensure the safety of man and machine. Against this background, Wieland Electric has upgraded its safety controller. The samos Pro Compact Plus is fit for motion monitoring.

No matter whether machines, systems, autonomous vehicles, lifts or wind turbines – wherever movement is involved, there can be no compromise on safety. As processes become increasingly automated, the monitoring of motion continues to gain importance. This can be optimally achieved using safety controllers and is why Wieland now has all functionalities needed for comprehensive rotational speed, rotational direction and position monitoring integrated in its samos Pro Compact.

The new Plus variant of the samos Pro Compact safety controller has six functions for reliable speed, position and direction monitoring. The motion sensors detect the required pulses to 70kHz, which the controller converts to speed, angle, position and direction. The motion functions, which are implemented according to EN 61800-5-2, compare the actual values with the limit values: If a permissible limit value or range is exceeded, appropriate safety measures come into effect – allowing the motor to be safely stopped, doors to be closed or locked, or even an additional alarm to be triggered.

Numerous safety functions can be realised with just one sensor element. Each functional module covers up to four ranges. In one controller, up to 25 rotational speed monitoring functions can be called up. This allows up to 100 speed or position ranges to be monitored by one basic module. In addition, the flexible units for limit values are proving to be extremely practical for international use of the samos Pro Compact Plus. Both the international SI standard system and the Imperial and US customary measurement system can be used.

The reliable SENC incremental encoder with HTL interface from Wieland Electric is available as an accessory. This allows speed and angle at the axes to be reliably measured, thereby achieving an unparalleled safety level to PLe and SIL3. It is suitable for all the reliable speed, direction and position monitoring of all machines with referencing run and for automatic guided vehicles (AGVs). The SENC incremental encoder is available in sizes 58mm and 90mm with hollow and solid shafts and with the matching accessories.

- Robust switch for use in the field

- Safe, economical planning of electrical systems

- Dedicated bus system

- Minimum effort, maximum safety

- Stops trespassing

- User-friendly programming software

- Project planning tool

- Wieland Electric debuts samos PRO MOTION

- samos PRO COMPACT makes it quick and easy to implement safety functions

- All-in-one motion monitoring