|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Machine Shop Equipment | >On the right track with VISI |

On the right track with VISI

09 December 2024

With the help of Hexagon’s VISI CAD/CAM/CAE software solution, model railway manufacturer PECO has streamlined production, improved efficiency, and brought over 3,000 product lines to life

AS ONE of the world’s leading manufacturers of model railways, PECO is a forward-looking family business that started trading back in 1946. To support its expansion, the Devon company relies on VISI CAD/CAM/CAE software from Hexagon in its design and manufacturing facility.

From the foundations that stem from manufacturing a simple coupling, PECO now runs a facility that makes over 3,000 product lines.

Keeping production on track

With a manufacturing site that hosts state-of-the-art technology, PECO relies on VISI CAD/CAM/CAE software for its workflows. "We use VISI throughout our manufacturing facility, from concept through to the final press or mould tool being created," said PECO’s Simon Cockerham.

"We have numerous licences of VISI throughout our many departments and we also use VISI to generate laser-cut wooden kits for customers with textures upon them. It is also used to create the instructions that will guide enthusiasts and users on how to assemble the equipment."

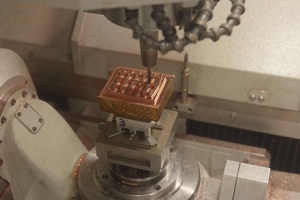

VISI plays an essential role in PECO’s production process

As one of the world’s leading PC-based CAD/CAE/CAM software solutions, VISI incorporates modules such as Modelling, Analysis, Mould Design, Flow, Electrode Design, Die Tool Design, 2.5, 3 and 5-axis Toolpaths, Blanks and Reverse. This provides PECO with the facility to create solid models, design, analyse, validate, and prepare mould tool geometries, and perform pre- and post-production analyses of plastic parts. With dedicated modules for creating electrodes, designing dedicated progressive die design and press tools, comprehensive machining strategies and even reverse engineering of editable solid models from scanned data - VISI provides the complete package for the company.

"A key reason why we use VISI is due to the complexity of our products," stated Cockerham. "We need jobs to be correct the first time. We also use very expensive machine tools from Roders, Sodick, and Hurco, as well as high-end peripheral equipment and cutting tools. VISI has always kept us safe throughout the entire process of generating these tools."

A holistic approach to innovation

The holistic Hexagon mould and die workflow removes blockers so the team can try new ideas. Cockerham explained: “We use VISI throughout most of our departments, especially within the wider ‘innovations department’. This means we use VISI for everything from design to producing wooden laser-cut kits for the factory to producing custom machinery for our production facilities. We also use VISI for all of our press and mould tooling too. The benefits of having VISI in the workplace are the integration between plot view, CAD/CAM, and the ability to create surface translations for mould flow analysis and laser ablation files. It streamlines integration between departments.”

Over the 17 years, PECO has standardised its workflows on Hexagon’s mould and die software and positively impacted its business. "We know we have saved a lot of time and money with VISI. The savings are down to the VISI software having all of the components and modules we require to take our products from concept through to production and export all around the world - all from under one roof," he concluded.

For more information:

Tel: 0333 241 4444

- No related articles listed

- Driving additive manufacturing forward

- Protecting workers from fumes and dust

- Mobile laser hardening robot helps boost efficiency

- Reusable industrial clamp

- Devices for TIG welding added

- Daylight quality lighting

- Thin film conversion coatings

- 3D printing used for Kew's dragons

- Tool order

- Customised blast cabinet upgrades armature repair