|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Labelling, marking and barcoding | >Ramp up resilience and efficiency in 2026 |

Ramp up resilience and efficiency in 2026

12 December 2025

THIS TIME of year is a period of reflection as well as forward planning. Industry experts are predicting not only more economic and geopolitical instability for 2026 but also increased cybersecurity threats, continued labour and skills shortages, and new regulatory burdens.

It’s challenging to know where to prioritise budget and focus, especially while consumers are demanding faster, greener deliveries and returns. Four in ten (40%) freight forwarders and 3PLs are said to be committing a quarter of their budget in 2026 to technology, with the lion’s share (44%) going on forecasting and visibility.

Modern retail fulfilment is defined by speed, precision, and customer expectations. It is distribution centres (DCs) that determine how quickly and accurately inventory flows across an entire retail network. As fulfilment complexity grows, there’s no room for bottlenecks, blind spots, or outdated systems.

Today’s DCs are under immense pressure, what with shifting order volumes, tighter SLAs, labour shortages and fragmented systems. They’re expected to do more than shift goods, they need to be dynamic hubs that can respond instantly to constant change. But many still rely on manual, disconnected workflows: over half (52%) say their order fulfilment processes remain largely, or entirely, manual. Such inefficiencies continue to hinder real-time responsiveness and limit the ability of DCs to scale operations during demand surges.

Think AIDC as well as AI

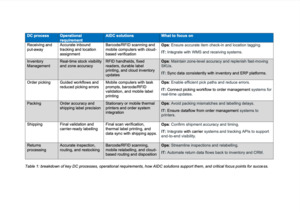

It’s time to rethink distribution execution and, while many in the supply chain are moving from AI experimentation to more widespread adoption, they should also consider the role of automatic identification and data capture (AIDC) technologies in improving efficiencies (see Table 1). AIDC technologies include barcode scanning, RFID, mobile computing, and thermal printing.

This tech helps digitise workflows and enables real-time visibility across all DC processes, enabling retailers to automatically capture accurate, real-time data at every step. It gives them real-time visibility, triggers automation processes, and enables more connected operations to turn their DCs into intelligent, high-performance fulfilment engines.

| DC process | Operational requirement | AIDC solutions | What to focus on |

| Receiving and put-away | Accurate inbound tracking and location assignment | Barcode/RFID scanning and mobile computers with cloud-based verification |

Ops: Ensure accurate item check-in and location tagging. IT: Integrate with WMS and receiving systems. |

| Inventory Management | Real-time stock visibility and zone accuracy | RFID handhelds, fixed readers, durable label printing, and cloud inventory updates |

Ops: Maintain zone-level accuracy and replenish fast-moving SKUs. IT: Sync data consistently with inventory and ERP platforms. |

| Order picking | Guided workflows and reduced picking errors | Mobile computers with task prompts, barcode/RFID validation, and mobile label printing |

Ops: Enable efficient pick paths and reduce errors. IT: Connect picking workflow to order management systems for real-time updates. |

| Packing | Order accuracy and shipping label precision | Stationary or mobile thermal printers and order system integration |

Ops: Avoid packing mismatches and labelling delays. IT: Ensure dataflow from order management systems to printers. |

| Shipping | Final validation and carrier-ready labelling | Final scan verification, thermal label printing, and data sync with shipping apps |

Ops: Confirm shipment accuracy and timing. IT: Integrate with carrier systems and tracking APIs to support end-to-end visibility. |

| Returns processing | Accurate inspection, routing, and restocking | Barcode/RFID scanning, mobile relabelling, and cloud-based routing and disposition |

Ops: Streamline inspections and relabelling. IT: Automate return data flows back to inventory and CRM. |

Table shows breakdown of key DC processes, operational requirements, how AIDC solutions support them, and critical focus points for success.

The right tools for the job

But DCs are tough environments and devices to improve inventory accuracy and visibility need to be rugged enough to withstand them. A handheld RFID reader like the RFR901 paired with the S50 enterprise mobile computer works well for cycle counts or, for greater automation, fixed RFID readers such as the FR900 can be placed at key checkpoints to track inventory movement automatically. And if RFID tags go missing or become unreadable, the Alpha-40L RFID mobile printer allows staff to relabel on the spot. Solutions and recommendations for other DC operations can be found in TSC Auto ID’s Retail Solutions Guide.

Modern DCs shouldn’t just be more efficient, they should also be smarter, more integrated, and ready to scale with tomorrow’s retail demands. The right AIDC solutions help drive efficiency and visibility in DCs and building resilience in the supply chain will depend on leveraging the sort of high-quality data this technology provides.

If you want faster decision-making, better resource allocation, scalable operations from receiving to returns then contact TSC Auto ID.

- Improve workplace efficiency with remote printer management

- Are printers and mobile devices your Achilles heel?

- Mitigate labour challenges by improving operational efficiencies

- Maximise operational efficiency with TSC Auto ID's space-saving industrial printers

- Counter five business challenges with linerless label printing

- Bring visibility to supply chain blind spots

- TSC Printronix Auto ID presents PEX-2000

- Desktop models

- 7000 label printers transform logistics network

- Improve productivity and sustainability with TSC Auto ID's linerless MB240 industrial printer