|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Safe radar system solution |

Safe radar system solution

31 July 2019

Safe even in the most rugged environments, and described by Pilz as a world first, is a new complete solution for protection zone monitoring based on radar technology.

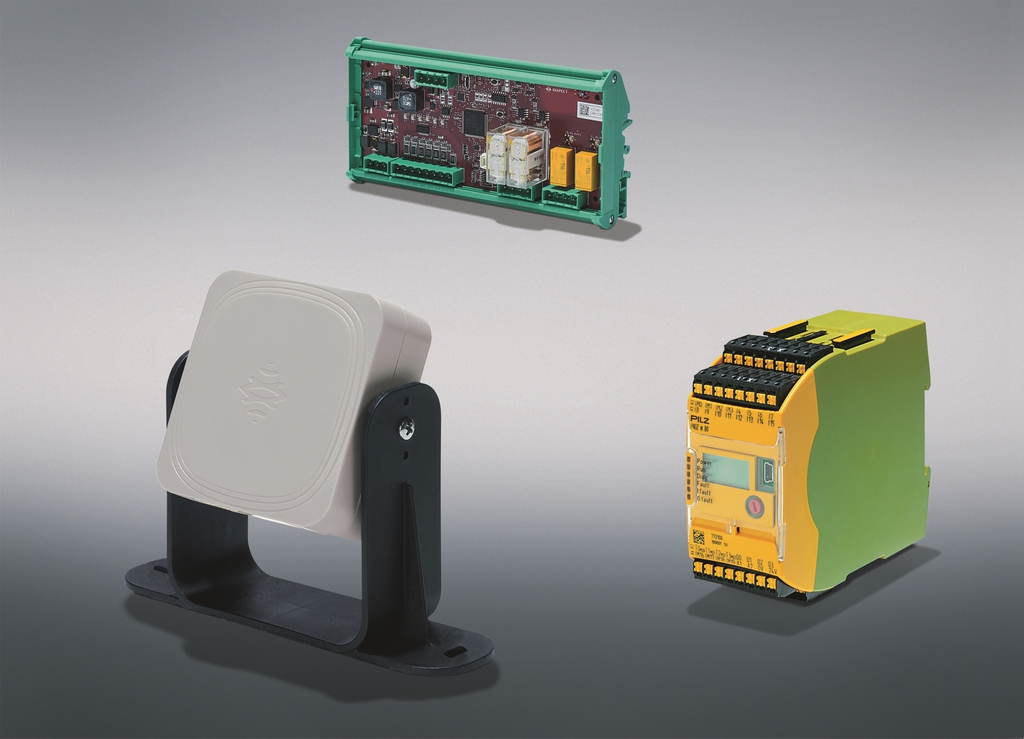

It comprises the safe radar system 'LBK System' from Inxpect S.p.A. and the configurable small controller PNOZmulti 2. As radar technology is fundamentally insensitive to external influences such as dust, rain, light, sparks or even shock, the solution provides safe, economical monitoring even in rugged environments where optoelectronic sensors and technologies cannot guarantee availability.

The safe radar system solution expands the Pilz portfolio in the safe sensor technology range PSEN.

The safe radar system solution comprises up to six radar sensors and one control unit, depending on application. In addition, the PNOZmulti 2 compact configurable safe controller is responsible for safety in the system.

In the event of a fault and when the protection zone is violated, PNOZmulti ensures that the reaction that is triggered is safe and reliable. The safe radar system solution can be used up to SIL 2, PL d, Category 2.

The safety-related functions covered by the system solution include 'detection function', i.e. when a machine is switched to a safe state as soon as a danger zone is violated, plus the restart interlock, which prevents the machine starting automatically if there is anyone in the danger zone.

The protection zone of each individual sensor is flexible and varies depending on installation height and inclination of the sensor. Each protection zone can be set up as wide - 110° horizontal/30° vertical – or narrow - 50° horizontal/15° vertical - with maximum depth of 4m. The layout of the total protection zone and system is flexible and can be configured to a maximum 15 x 4m using six sensors in series to create a linear barrier.

Safety and productivity

Typical applications can be found in heavy industry, where dirt, dust, swarf or welding sparks, bright light and shock are prevalent. This includes steel processing, foundries or woodworking. Outdoors, the radar system solution safeguards cranes and floor conveyor systems, bulk cargo ports or storage facilities even in fog, snow and up to moderate rain.

- Training course schedule

- PNOZ m C0 - as narrow as a safety relay, but as powerful as a safety controller

- New modular operating mode and access permission system

- Upgrades:The need to conform

- Interactive PUWER inspection

- Door guard switch

- Light curtain testing

- Machine safety webinars

- Control system with application simulation

- Human-robot collaboration