|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Industry 4.0 | >Modicon Edge I/O NTS - Simplifying maintenance and improving data continuity |

Modicon Edge I/O NTS - Simplifying maintenance and improving data continuity

09 May 2025

Plant managers can prepare for the data-driven future with an input/output solution that delivers consistent value in all industrial applications.

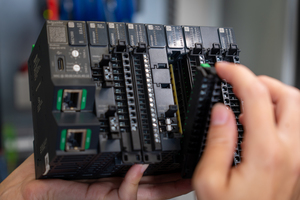

SCHNEIDER ELECTRIC'S new Modicon Edge I/O Network Terminal Slice (NTS) is a game-changer for plant managers who want future-proofed data networks across manufacturing, packaging, food and beverage, life sciences, water/wastewater, mining, minerals & metals, critical infrastructure, or energy and chemicals.

The new-generation I/O platform is designed for long life, reliability and scalability to connect to a wide variety of smart devices, meters, sensors and edge devices that are distributed widely across a facility.

Reliability

The Modicon Edge I/O NTS will cut costs by reducing mean time to repair and unplanned downtime. It achieves this with a robust design that withstands the industrial environment. Until now, I/O modules have had limited hot swap capability. However, the Modicon Edge I/O has no restrictions, which avoids the need to power down control systems to swap out modules. In turn, this empowers users to react quickly ensure operations can continue, saving valuable minutes of costly downtime.

In addition, a web interface supports reliability as plant managers can log in remotely for diagnostics, troubleshooting and commissioning with or without the upstream PLC controller attached.

Built-in cyber protection

The rising threat of cyber-attack is a common barrier when it comes to digital transformation as greater interconnectivity introduces new vulnerabilities. However, cybersecurity can be strengthened at the I/O level to reduce the risk of ransomware and its resulting safety risk for operators and the wider plant.

The Modicon Edge I/O NTS has built-in security features that will help safeguard infrastructure and data. It complies with IEC 62443-4-2, provides role-based access control and supports encrypted communication to isolate threats, helping contain breaches. As cyber awareness increases, secure I/O is becoming a critical element in future-proofing industrial design.

Future-proofing

As with any technology deployment, plant managers must look at the immediate needs while considering future requirements, asking if a solution can scale with a business and deliver on required flexibility. This is especially crucial in fast-moving sectors like manufacturing, where reacting to customer demand is critical for remaining competitive. By specifying the Modicon Edge I/O NTS, plant managers can create a foundation for future growth, with a modular design that adapts to new production requirements.

The Modicon Edge I/O NTS enables safer, smarter and more efficient operations while future-proofing digital transformation.

The modular I/O system is built on a trusted heritage stretching back to the first Modicon PLC in 1968. It is compatible with a wide variety of PLCs and communications protocols.

To support customers, Schneider Electric has launched a product configurator for systems integrators to configure control systems based on PLC controllers and I/O modules before purchase. It’s possible to build up a system with all the digital and analogue input and output, communications and power modules they need for a project. The online tool will provide a full Bill of Materials including any accessories required, together with 2D and 3D drawings and 360 degree dimensioned views. The BOM can then be easily ported into a shopping basket for price and availability information.

Ultimately, the Modicon Edge I/O NTS is a step forward in communications modules that provides future proofing through reliability, scalability and integration support.

- Twickenham prepares for Rugby World Cup

- Schneider & Cisco partner to bridge OT/IT in building management systems

- VP appointment

- European lessons for UK manufacturers

- Schneider Electric appoints Chris Collins as country president for Ireland

- Quality matters

- Schneider Electric announces ClimaSys Smart Ventilation System

- A new era of industrial computing

- On course to meet carbon neutral target

- Power and energy meter

- Technology and Open Standard data enabling smart maintenance

- Broadband sensors: Pinpointing leaks in compressed air systems

- Mechanised welding, cutting and Industry 4.0

- Tomorrow’s tech is here today

- Investment in infrastructure, innovation and people

- Getting to 4.0 – one hard-won gain at a time

- Digital transformation in the chemical industry: White paper

- Digital industry around the world

- Guidance via AR

- How machine learning is transforming predictive maintenance