|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Condition monitoring | >Temperature monitoring of incinerator |

| Home> | Premises management/maintenance | >Waste management and recycling | >Temperature monitoring of incinerator |

Temperature monitoring of incinerator

31 July 2018

Compiling thermal images of objects that move at extremely slow speeds is a challenge in its own right.

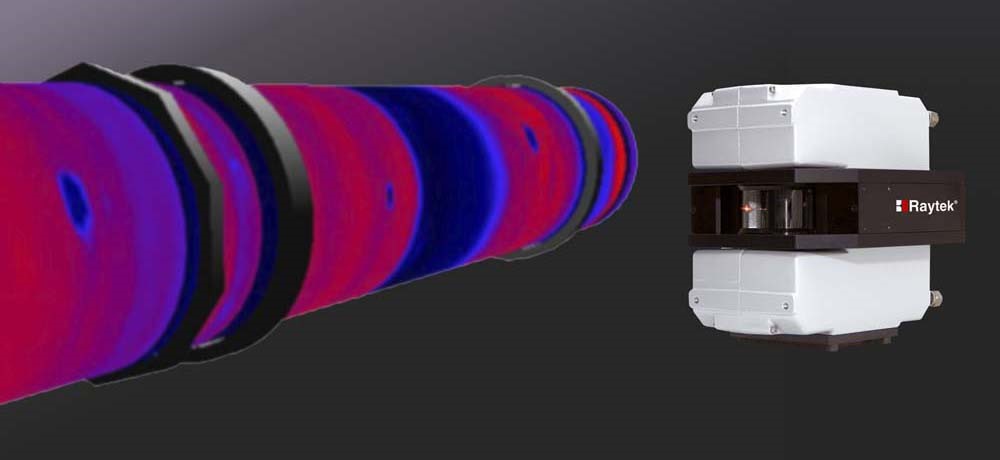

Fluke Process Instruments says it has solved this measuring task for a chemical waste incineration plant. Hazardous wastes are combusted in a rotary kiln that turns at 4 to 6 revolutions per hour. Over time, the refractory brick protecting the kiln wall degrades and has to be replaced. This used to be done in regular intervals with a big safety margin to prevent serious damage to the incinerator or even leakage of hazardous materials.

Fluke Process Instruments supplied a Raytek CS210 infrared line-scanning system that is able to synchronize thermal images at speeds as low as 2 revolutions per hour. It detects temperature deviations across the entire kiln shell and provides the plant operator with information about the state of the incinerator. The kiln shell temperature ranges between 100 °C and 500 °C. Hotspots point to refractory loss or wear. The installation of the monitoring system is said to have resulted in significant savings due to an extended operational life of the refractory and reduced downtimes.

- Infrared pyrometer for glass production

- Infrared thermometer for steelworks

- Handheld infrared thermometer

- Sensors now with Ex i certification

- High-temperature pyrometers fit for harsh environs

- Endurance infrared thermometer

- Thermal imaging and furnace surveys

- Water cooled temperature sensors

- Processor box for remote configuration

- Turnkey temperature monitoring