|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Cutting systems | >Cutters cut sample sectioning time |

Cutters cut sample sectioning time

07 November 2019

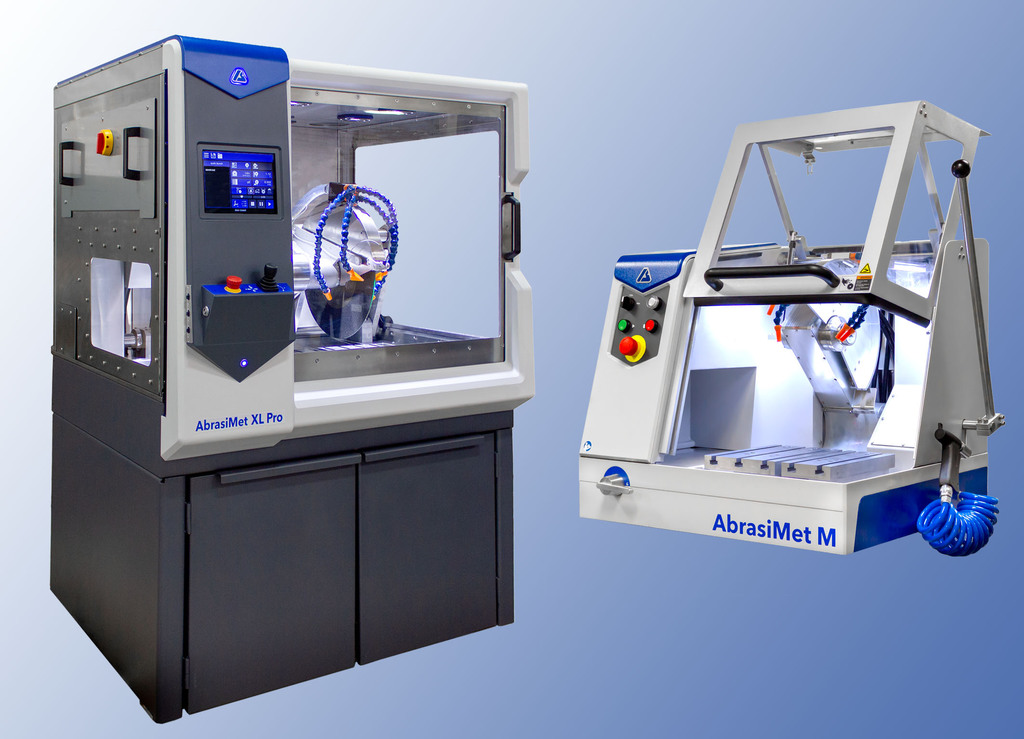

Two new sectioning machines from Buehler are designed for time-saving and cost-efficient sectioning of samples with high-quality results.

AbrasiMet XL Pro is a durable, floor-standing automatic cutting machine providing high performance in harsh industrial environments and capable of handling sample diameters up to 178mm using chop, linear feed, and planar cutting modes. The system accommodates blade diameters from 356 to 457mm. Its large cutting chamber and powerful 10kW motor ensures repeatable sectioning with consistently high quality, even when dealing with very hard materials and/or large samples. An intuitive touchscreen interface allows users to start the section process with ease and to create and save multiple sectioning programs quickly for later access. Further features contributing to the cutter's efficiency are toolless blade replacement process and a rapid setup for a cut with the help of a multi-function joystick, an alignment laser and a bright lit cutting chamber. The machine is equipped with a filtration screen to remove swarf from the coolant, and a double-chamber recirculating tank that facilitates efficient cleaning.

AbrasiMet M is a manually operated bench-top cutter designed for highly consistent cuts and high sample throughput, and, like AbrasiMet XL Pro, is said to hold a leading position in its device class in terms of efficiency and power. The compact and sturdy cutter utilises 254 or 305mm diameter blades. A time-saving dual-blade feature enables two parallel cuts to be performed in one operation. The sliding door allows easy access to the large cutting chamber to quickly and precisely position samples for cutting. A powerful 4kW motor and ergonomic cutting arm, whose length and angle can be adjusted to suit the individual user, provide for a smooth and efficient cutting motion. As in the case of the AbrasiMet XL Pro, no tools are required to change abrasive blades.

Sarah Beranek, global director of innovation at Buehler, comments: "In today's industrial environment, high throughput in industrial quality control labs is key to improving efficiency in production. Designed for high-use environments, the durable AbrasiMet cutters contribute essentially towards achieving this goal, by accelerating the provision of high-quality samples."

- New diamond grinding discs on show

- New metallographic laboratory opens

- Hardness testers and grinder-polishers

- Metallographic products and materials testing solutions

- New hardness tester delivers flexibility to industry and research

- Buehler celebrates 100 years of Wilson Hardness brand

- Grinder-polishers for demanding applications and high-volume environments