|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >Vacuum pumps: Efficiency matters |

Vacuum pumps: Efficiency matters

14 March 2019

Vacuum pumps are important components in the packaging of fresh foodstuffs, but which vacuum pump achieves the highest efficiency factor?

A direct comparison can answer this question, as long as the test setup is appropriate. A recently-published comparison study suggests the superiority of an oil-sealed screw vacuum pump. However, according to Busch, this result came about using a test setup that seems very unrealistic. Independent testing organisation TÜV Süd has also carried out a comparison of the vacuum pumps involved, using a simulation of a standard industrial process. Under these conditions, Busch says the result is clearly in favour of the oil-lubricated rotary vane vacuum pump.

This article compares the two comparison tests. For the sake of clarity, they are referred to as Test 1 and Test 2. The oil-sealed screw vacuum pump is abbreviated as SVP and the oil-lubricated rotary vane vacuum pump as RVVP.

Test 1

This test was initiated by the manufacturer of the oil-sealed screw vacuum pump (SVP). The company mainly specialises in compressors, and the machine in question is a derivative of compressor technology. It was compared to an R 5 RA 0630 C oil-lubricated rotary vane vacuum pump (RVVP) from Busch. However, Busch says the test setup does not allow a realistic comparison for several reasons:

The test cycle simulated various vacuum-supported processes. However, production breaks, including nightly down times during which the RVVP, unlike the SVP, continued to run, were obviously also included. In the test, the SVP was operated as part of a system with frequency converters and integrated control system that stopped the vacuum pump during breaks. On the other hand, the RVVP was apparently connected as an isolated machine that ran continuously at full power.

The continuously running vacuum pump naturally consumed more electricity than its regulated counterpart, which was automatically stopped in the breaks. The RVVP could have been equipped with a frequency converter and a control system – Busch offers such a version of this vacuum pump. This would have created similar starting conditions. According to Busch, the description of the test lacks precise information about such essential framework conditions.

Due to its design, an RVVP has in general the highest power consumption in the start-up phase between atmospheric pressure and approximately 300mbar. However, the power consumption decreases as the inlet pressure decreases. A SVP, on the other hand, consumes approximately the same amount of power between atmospheric pressure and ultimate pressure. This means, says Busch, that an RVVP requires considerably less power in the operational range between ultimate pressure and 100mbar than a SVP.

Test 2

The second comparison test was carried out by independent testing organisation TÜV Süd. The same vacuum pumps were used as in Test 1. However, this time real operation was simulated, without breaks or nightly shutdowns. Test 2 simulated the working cycle of a vacuum packaging machine. This is a common use for vacuum pumps in industry. As is often the case with such applications, both vacuum pumps were additionally supported by an identical vacuum booster. In addition, test setup and procedure were checked by a well-known manufacturer of vacuum packaging machines and confirmed as a realistic simulation.

As an application example, a packaging machine with a large chamber volume was chosen, such as is used in the packaging of meat or cheese products. Typically, such a machine with automatic product supply handles several cycles per minute.

In the test, the machine was simulated using a 300L chamber and an 11.5m long pipe system between the chamber, vacuum booster, and vacuum pump. The chamber was evacuated cyclically to a vacuum level of 5 mbar.

The time for evacuation depended on the performance of the vacuum pumps. The time between evacuation cycles was set at 14 seconds – a typical time span for this size of packaging machines. The required pump-down time of the vacuum pumps and their energy consumption were recorded.

Results

These tests showed the rotary vane vacuum pump evacuated faster and consumed less energy than the screw vacuum pump. Depending on the set speed of the RVVP, this results in further shortened pump-down times or increased energy savings. For example, Busch says the RVVP is 11% faster in 40 Hertz mode and saves 42% in power consumption by comparison.

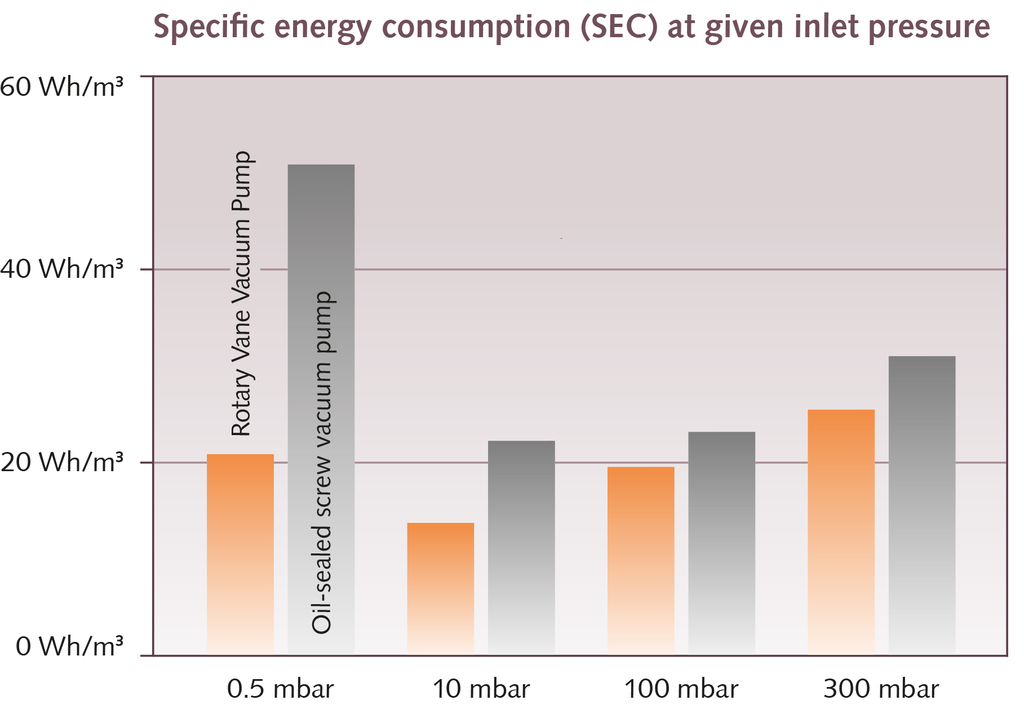

In addition to the pump-down time and the energy consumption, pumping speed and energy consumption were also measured during the test as a function of the inlet pressure. The specific energy consumption (SEC) at different vacuum levels was calculated from these measured values. This gives precise information about how many watts are needed to extract one cubic meter of air per hour to reach a certain vacuum level. Busch says the RVVP is superior to the SVP in all vacuum levels, with energy savings of between 13 and 73%. At the vacuum level of 10mbar (typical in practice), the RVVP consumed 38% less energy than the SVP.

- Busch Vacuum Solutions Presents the Intelligent TYR PLUS Rotary Lobe Blower

- OTTO Digital Services for vacuum systems

- New Busch success story - No high-quality porcelain without vacuum

- Saving energy with intelligent vacuum technology

- Vacuum pumps: Technology and applications

- Claw vacuum pump

- Liquid ring vacuum pumps

- Busch Group launches new website

- Energy-efficient vacuum supply

- Energy efficiency focus