|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Spiral heat exchanger |

ARTICLE

Spiral heat exchanger

25 January 2013

The latest addition to Alfa Laval's spiral heat exchangers range, the allstainless steel ALSHE VAP, is a standardised exchanger available with fast delivery times, designed specifically for use as a vapouriser in a wide

The latest addition to Alfa Laval's

spiral heat exchangers range, the allstainless

steel ALSHE VAP, is a

standardised exchanger available

with fast delivery times, designed

specifically for use as a vapouriser in

a wide range of process industries.

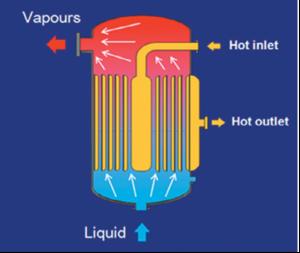

Unlike a conventional spiral heat exchanger in which media flow in direct counter-current flow, the ALSHE VAP is configured so that one stream is in spiral flow while the other flows across it, in parallel to its axis. The spiral flow channel generally accommodates the heating medium while the cross flow channel is dedicated to the fluid to be vapourised or boiled. This design ensures that the unit can handle high liquid velocities in the closed, spiral channel and, on the boiling side, the large cross-flow area with a relatively low physical height makes the unit suitable for operation at low pressure or under vacuum.

The four models in the range handle temperatures up to a max. of 300°C and min. of -100°C.

Unlike a conventional spiral heat exchanger in which media flow in direct counter-current flow, the ALSHE VAP is configured so that one stream is in spiral flow while the other flows across it, in parallel to its axis. The spiral flow channel generally accommodates the heating medium while the cross flow channel is dedicated to the fluid to be vapourised or boiled. This design ensures that the unit can handle high liquid velocities in the closed, spiral channel and, on the boiling side, the large cross-flow area with a relatively low physical height makes the unit suitable for operation at low pressure or under vacuum.

The four models in the range handle temperatures up to a max. of 300°C and min. of -100°C.

MORE FROM THIS COMPANY

- Heat recovery

- Large scale heating & cooling

- Sludge treatment order

- Free guide to Legionnaires' disease

- Alfa Laval appoints Moody Direct as authorised distribution partner

- Takes the pressure

- Demystifying the heat transfer process

- Virtual showroom in 3d

- Improving efficiency in plant pump processes

- Designed to cool transformer oil

OTHER ARTICLES IN THIS SECTION