|

Edward Lowton

Editor |

|

ARTICLE

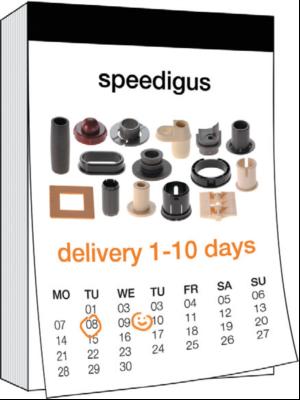

Moulded parts in 24h

25 January 2013

Polymer specialist igus has developed a new tooling method for injection moulding which can get custom designed parts delivered in less than 24h. There is no minimum order so speedigus is suitable for 'one-offs', protot

Polymer specialist igus has developed

a new tooling method for injection

moulding which can get custom

designed parts delivered in less than

24h. There is no minimum order so

speedigus is suitable for 'one-offs',

prototyping, low

volumes and bridge

tooling.

"Standard tool manufacture can take four to eight weeks and is normally only available for minimum orders of around 5000 pieces," says Matt Aldridge of igus UK. "But, with speedigus you can get a single part in just one day. All we need is the required quantity and a 3D CAD file of the part." igus currently manufactures speedigus parts in eight iglidur materials (iglidur G, J, W300, X, M250, P, A180 and H2) as well as igumid G, the igus E-Chain material; the designer selects the material best suited to the application, using an online selection tool: www.igus.co.uk/speedigus.

iglidur materials are maintenance and lubricant free, long lasting and have a low coefficient of friction.Most speedigus parts manufactured to date are custom design components that have a bearing function.

The igus useful service life calculation program is still valid.

Engineers can also draw on other features of iglidur materials, such as low weight with electrical conductivity, chemical resistance or high temperatures. The speedigus system can accommodate parts that fit into an envelope of up to 475 x 750 x 200mm, with wall thicknesses to 0.5mm

"Standard tool manufacture can take four to eight weeks and is normally only available for minimum orders of around 5000 pieces," says Matt Aldridge of igus UK. "But, with speedigus you can get a single part in just one day. All we need is the required quantity and a 3D CAD file of the part." igus currently manufactures speedigus parts in eight iglidur materials (iglidur G, J, W300, X, M250, P, A180 and H2) as well as igumid G, the igus E-Chain material; the designer selects the material best suited to the application, using an online selection tool: www.igus.co.uk/speedigus.

iglidur materials are maintenance and lubricant free, long lasting and have a low coefficient of friction.Most speedigus parts manufactured to date are custom design components that have a bearing function.

The igus useful service life calculation program is still valid.

Engineers can also draw on other features of iglidur materials, such as low weight with electrical conductivity, chemical resistance or high temperatures. The speedigus system can accommodate parts that fit into an envelope of up to 475 x 750 x 200mm, with wall thicknesses to 0.5mm

MORE FROM THIS COMPANY

- Real twister

- Green approach to energy chains

- Aluminium support trays for energy chains in corrosive environments

- Safe cable guidance even in confined spaces

- Long service life in 100% humidity

- Aluminium support trays for energy chains

- Bevel gears for lubrication-free motion

- In search of plastic plain bearing applications

- Cambridge students gear up for another season of electric boat innovation with support from igus

- Bearing service

RELATED ARTICLES

- No related articles listed

OTHER ARTICLES IN THIS SECTION