|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Welding | >Offering plasma welding expertise |

ARTICLE

Offering plasma welding expertise

25 January 2013

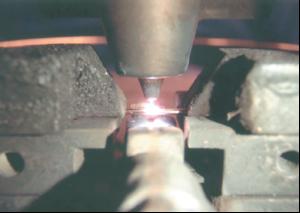

William Hughes is using plasma welding processes to manufacture a variety of wire products for industries ranging from consumer electrical goods to automotive. The semi-automatic plasma welding process is used by the c

William Hughes is using plasma

welding processes to manufacture a

variety of wire products for

industries ranging from consumer

electrical goods to automotive.

The semi-automatic plasma

welding process is used by the

company to join round phosphor

bronze or stainless steel wire, making

2D or 3D forms. Hexagonal wire can

also be processed if required.

Almost any diameter (including very small sizes) can be accommodated - only a change of clamping plates is needed. In terms of wire diameter, this is typically 0.75 or 0.9mm.

A rigorous failure test mechanism is in place to ensure that high quality plasma-welded parts are always supplied.

Almost any diameter (including very small sizes) can be accommodated - only a change of clamping plates is needed. In terms of wire diameter, this is typically 0.75 or 0.9mm.

A rigorous failure test mechanism is in place to ensure that high quality plasma-welded parts are always supplied.

MORE FROM THIS COMPANY

- Springs: Sole supplier status

- Passivation explained and demonstrated

- Protecting parts during storage and transportation

- Ultrasonic cleaning

- William Hughes expands aerospace quality programme

- Rapid prototyping

- Bulgaria success

- Clean bill of health

- 3D measurement scanner helps boost accuracy

- New capacity springs into action at Wm. Hughes

OTHER ARTICLES IN THIS SECTION