|

Edward Lowton

Editor |

|

| Home> | Health, Safety & Welfare | >Plant and machinery safety | >Machine speed monitor |

ARTICLE

Machine speed monitor

25 January 2013

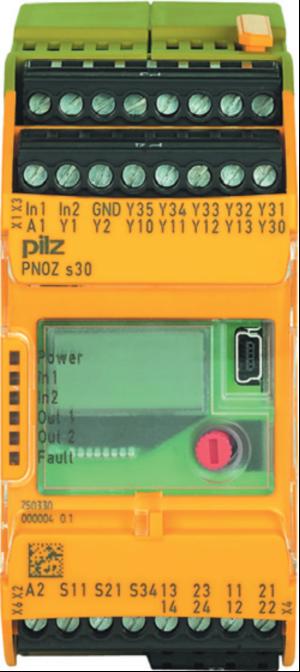

A safety relay that monitors the safe standstill, over-speed and direction of rotation of a variety of machines is now available from Pilz Automation Technology. The PNOZ s30 speed monitor can be used for applications

A safety relay that monitors the safe

standstill, over-speed and direction

of rotation of a variety of

machines is now available

from Pilz Automation

Technology. The PNOZ s30

speed monitor can be used

for applications from small

packaging machines to large

rotating machinery as used,

for example, in paper mills

and web-based printing

machines.

In accordance with the new Machinery Directive, when a machine drive is brought to a standstill, the operating status must be safely monitored and maintained.

Part of Pilz Automation Technology's PNOZsigma range, the PNOZ s30 can be connected to many motor feedback systems which use incremental encoders or proximity sensors to provide a speed signal. A rotary knob with key function (push and turn) and an integrated display enable users to enter their own data via an intuitive menu structure. These parameters are stored on a chip card. The permanent display informs users about current speed during machine operation, while integrated LCDs show the state of the output relay.

Safety functions include standstill monitoring combined with safe position monitoring at standstill.

In accordance with the new Machinery Directive, when a machine drive is brought to a standstill, the operating status must be safely monitored and maintained.

Part of Pilz Automation Technology's PNOZsigma range, the PNOZ s30 can be connected to many motor feedback systems which use incremental encoders or proximity sensors to provide a speed signal. A rotary knob with key function (push and turn) and an integrated display enable users to enter their own data via an intuitive menu structure. These parameters are stored on a chip card. The permanent display informs users about current speed during machine operation, while integrated LCDs show the state of the output relay.

Safety functions include standstill monitoring combined with safe position monitoring at standstill.

MORE FROM THIS COMPANY

- New modular operating mode and access permission system

- Light curtain testing

- Electrically activated E-STOP pushbuttons

- Safe radar system solution

- Safe machinery, step-by-step

- Maximise safety performance

- All-in-one safety gate

- EN ISO 14119 standard

- Control system with application simulation

- 360° approach to machinery safety

OTHER ARTICLES IN THIS SECTION