|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Maintenance products | >Proactive in cutting costs |

ARTICLE

Proactive in cutting costs

25 January 2013

A Predictive Maintenance (PdM) programme can bring savings in maintenance costs and result in a reduction in downtime.However, John Atkinson of C-Cubed believes that by moving to Proactive Maintenance companies can reduc

A Predictive Maintenance (PdM) programme can bring

savings in maintenance costs and result in a reduction in

downtime.However, John Atkinson of C-Cubed believes that

by moving to Proactive Maintenance companies can reduce

the cost by a factor of almost a half again

So what is Proactive Maintenance? Put quite simply, it is finding out what causes a fault to occur and fixing the cause rather than just the fault itself. For example, if a bearing was supposed to last for 10,000 hours but it wore out after just 2000 hours, we need to find out why it failed prematurely and fix the problem, and not simply keep on replacing the bearing every 2000 hours. In the case of a bearing, the problem could very well be due to misalignment or out-of-balance, perhaps the two biggest causes of premature bearing failure after lack of lubrication, and problems that these days can be detected and corrected very easily using modern tools.

There are also low cost, easy to use maintenance tools available now to monitor and control lubrication and hence eliminate that as a source of bearing failure.

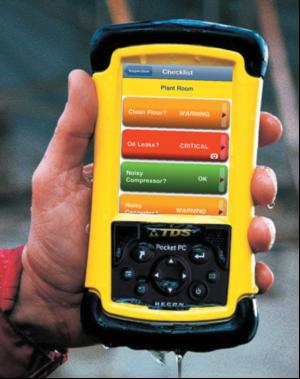

Powerful and affordable, rugged (waterproof and droppable) handheld PCs (see Figure 1) are now available that can perform the tasks listed in Table 2 simply by connecting the appropriate sensors. In many cases the sensors can even be connected wirelessly using Bluetooth communications, a feature that is more or less standard on practically all portable units these days. As a result it is possible to utilise a single windows-based platform for all our Proactive Maintenance tool requirements.

While using predictive maintenance tools, experienced service and maintenance personnel bring another valuable skill to the job - they use their eyes and ears. The vibration analyser may well indicate that a bearing will fail in two months - but why has the failure happened? The experienced person may notice that the drive coupling is worn, report it to the correct department and ensure it is replaced along with the bearing as soon as practical. This is another example of what is meant by Proactive Maintenance.

But what if the coupling wear wasn't spotted? - The bearing would be changed but would soon wear out again. Instead of relying solely on experienced staff, new tools are available which lead the user through the process of making inspections and provide clear and documented reports, which can be sent out automatically via email to generate alerts and workflow tasks.

Inspections The problems with carrying out inspections include the chance that something may be missed or, even if spotted, the corrective action doesn't take place. One way these problems can be avoided is through the use of an Inspection Tool. A typical example is Pocket Inspection, which presents the user with a list of clearly defined questions that need to be answered and can then be used to ascertain the condition of an asset for example. The asset can be anything from a complex machine to a plant room or office, with questions such as 'Is the floor clean?', 'are the lights working?', 'has the fire extinguisher been serviced to date?' and so on. The answers to these questions are then stored in the portable device and when the information is transferred to a host PC any exceptions (alarms, warnings and so on) are used to generate 'task lists' that initiate the corrective maintenance tasks required. These task lists can take many forms from simple emails to fully integrated workflow tasks in proprietary systems such as SAP.

Simple-to-use, affordable, rugged and reliable tools now make it possible to 'close the loop' and implement proactive maintenance in-house. High cost of equipment and training may have put people off in the past and forced them to rely on hiring third party support for these tasks, and often limiting its application to high cost and critical processes. But this is simply not the case these days. Easy to use Windowsbased software with which most people are familiar means that anyone who can send an email or use a mobile phone can be a plant inspector. Nowadays there is simply no excuse for not implementing Proactive Maintenance.

So what is Proactive Maintenance? Put quite simply, it is finding out what causes a fault to occur and fixing the cause rather than just the fault itself. For example, if a bearing was supposed to last for 10,000 hours but it wore out after just 2000 hours, we need to find out why it failed prematurely and fix the problem, and not simply keep on replacing the bearing every 2000 hours. In the case of a bearing, the problem could very well be due to misalignment or out-of-balance, perhaps the two biggest causes of premature bearing failure after lack of lubrication, and problems that these days can be detected and corrected very easily using modern tools.

There are also low cost, easy to use maintenance tools available now to monitor and control lubrication and hence eliminate that as a source of bearing failure.

Powerful and affordable, rugged (waterproof and droppable) handheld PCs (see Figure 1) are now available that can perform the tasks listed in Table 2 simply by connecting the appropriate sensors. In many cases the sensors can even be connected wirelessly using Bluetooth communications, a feature that is more or less standard on practically all portable units these days. As a result it is possible to utilise a single windows-based platform for all our Proactive Maintenance tool requirements.

While using predictive maintenance tools, experienced service and maintenance personnel bring another valuable skill to the job - they use their eyes and ears. The vibration analyser may well indicate that a bearing will fail in two months - but why has the failure happened? The experienced person may notice that the drive coupling is worn, report it to the correct department and ensure it is replaced along with the bearing as soon as practical. This is another example of what is meant by Proactive Maintenance.

But what if the coupling wear wasn't spotted? - The bearing would be changed but would soon wear out again. Instead of relying solely on experienced staff, new tools are available which lead the user through the process of making inspections and provide clear and documented reports, which can be sent out automatically via email to generate alerts and workflow tasks.

Inspections The problems with carrying out inspections include the chance that something may be missed or, even if spotted, the corrective action doesn't take place. One way these problems can be avoided is through the use of an Inspection Tool. A typical example is Pocket Inspection, which presents the user with a list of clearly defined questions that need to be answered and can then be used to ascertain the condition of an asset for example. The asset can be anything from a complex machine to a plant room or office, with questions such as 'Is the floor clean?', 'are the lights working?', 'has the fire extinguisher been serviced to date?' and so on. The answers to these questions are then stored in the portable device and when the information is transferred to a host PC any exceptions (alarms, warnings and so on) are used to generate 'task lists' that initiate the corrective maintenance tasks required. These task lists can take many forms from simple emails to fully integrated workflow tasks in proprietary systems such as SAP.

Simple-to-use, affordable, rugged and reliable tools now make it possible to 'close the loop' and implement proactive maintenance in-house. High cost of equipment and training may have put people off in the past and forced them to rely on hiring third party support for these tasks, and often limiting its application to high cost and critical processes. But this is simply not the case these days. Easy to use Windowsbased software with which most people are familiar means that anyone who can send an email or use a mobile phone can be a plant inspector. Nowadays there is simply no excuse for not implementing Proactive Maintenance.

MORE FROM THIS COMPANY

- What does vibration tell us about machine condition?

- Inspection unit

- Inspection systems

- TPI acquires C-Cubed

- Vibration analysis

- Vibration meter

- How do you know when a bearing needs to be replaced?

- C-Cubed shall be demonstrating a range of vibration analysers at Plant & Asset Management 2014

- Vibration meter

- Tools on show

OTHER ARTICLES IN THIS SECTION