|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Bearings | >How do you know when a bearing needs to be replaced? |

How do you know when a bearing needs to be replaced?

16 January 2025

Monitoring higher-frequency vibrations beyond the ISO range can help pinpoint bearing damage early, enabling maintenance teams to set precise alarm levels and act proactively to extend machinery life

ISO VIBRATION guidelines provide a solid foundation for setting alarm levels in Condition-Based Maintenance (CBM) programs, using a “traffic light” system to indicate machine status - acceptable (green), warning (amber), and critical (red).

Uncorrected faults such as unbalance, misalignment and looseness will lead to premature bearing failure and potential damage to a machine.

Detecting bearing wear

But what about the bearings themselves? How do you know when a bearing needs to be replaced?

The ISO frequency range will not detect bearing wear, unless the bearing is so badly worn it is on the brink of collapse. This is because most bearing noise results from high frequency vibrations of the bearing elements and is in the frequency range above 1kHz, the upper limit of the ISO range.

This is the typical “whine” you hear from a worn bearing. In practice, it is usually inaudible until the bearing about to fail. Fortunately, a vibration analyser can detect this noise well before it gets to that point.

Understanding Bearing Damage Units (BDU)

Although there are no formally agreed standards for acceptable levels of bearing noise, some “de facto” industry standards have been established to quantify bearing condition, such as the use of Bearing Damage Units (BDU).

As a “rule of thumb” for typical induction motors running at roughly 1500 RPM in Europe (1800 RPM in North America) vibration analysts consider 1g (100 BDU) as the threshold for a worn bearing. Hence, it is tempting to think of BDU as “percentage bearing wear” for typical motor run speeds. Manufacturers of CBM instruments will sometimes give guidelines for acceptable levels of bearing noise, but to diagnose a bad bearing the best thing to do is to look at the TREND of the BDU readings.

Establishing baselines and alarm levels

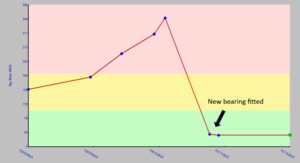

The example VibTrend plot shown here shows the BDU readings of a large bearing on a wire saw taken roughly every two weeks. The decision was taken to replace the bearing after the reading reached a level of roughly 350 BDU. The readings taken after the bearing was replaced then established an approximately 30 BDU baseline for a "known good" (i.e. new) bearing.

Comparisons between "known good" bearings and bearings that are known to be worn soon enables patterns to be observed. In the case described here, alarm levels for similar bearings were subsequently set at 100 BDU for a Warning (amber) and 200 BDU for Critical (red).

Fortunately, simple-to-use, low-cost vibration analysers capable of trending readings are available. The TPI 9080 comes complete with VibTrend PC based trending and reporting software that includes automatic report generation and email notification of alarms, implementing a full CBM solution. The TPI 9080 can store lists (routes) of machines to be measured (up to 1,000) with full vibration waveform and frequency spectrum capture for each.

For more information:

Tel: +44 1293 530196

- Petrochemical plant solves bearing failure problem

- Chance to learn more about bearings

- Enhanced efficiency

- Bearing success

- Change of bearing cuts plant's costs

- Custom bearing capability

- Going to extremes to deliver savings

- Providing a boost to bearing life

- Box of bearings

- Engineered Arts wins manus award