|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Monitoring and targeting | >Helping to cut energy use and CO2 emissions |

ARTICLE

Helping to cut energy use and CO2 emissions

04 March 2013

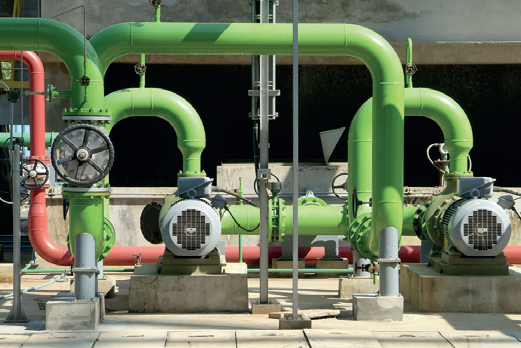

The SKF Energy Monitoring Service - Pump Systems, a BeyondZero Portfolio product, has helped a customer identify a potential reduction in CO2 emissions.

The SKF Energy Monitoring

Service - Pump Systems, a

BeyondZero Portfolio

product, has helped a customer

identify a potential reduction in CO2

emissions.

The customer, operating in the pulp and paper industry, identified an energy improvement potential of 70% for one factory by monitoring just eight out of its 300 pumps.

Through monitoring and optimising the efficiency of those pumps, it was calculated that the factory could cut its annual electricity demand by up to 2500MWh, corresponding to 1% of the factory total electricity use. In terms of CO2 emission reduction, this equates to about 1900t/year (according to world power grid mix CO2 factor of 0.749kg CO2/kWh).

Energy Monitoring Service (EMS) for pump systems typically shows an energy use savings potential can be greater than 20% in non-monitored pump systems; and year-to-year savings of about 5% in those systems

The customer, operating in the pulp and paper industry, identified an energy improvement potential of 70% for one factory by monitoring just eight out of its 300 pumps.

Through monitoring and optimising the efficiency of those pumps, it was calculated that the factory could cut its annual electricity demand by up to 2500MWh, corresponding to 1% of the factory total electricity use. In terms of CO2 emission reduction, this equates to about 1900t/year (according to world power grid mix CO2 factor of 0.749kg CO2/kWh).

Energy Monitoring Service (EMS) for pump systems typically shows an energy use savings potential can be greater than 20% in non-monitored pump systems; and year-to-year savings of about 5% in those systems

MORE FROM THIS COMPANY

- Condition monitoring service expanded

- Food industry compliant bearings

- Extended range of ball bearings available with high performance seal option

- Looking ahead

- Sealing solution for the metals industry

- Ceramic bearings: Demand grows

- Food industry compliant bearings

- Rolling bearings in paper machines

- Inverted roller screws engineered for high performance

- Reality check: from technology to value in Industry 4.0

OTHER ARTICLES IN THIS SECTION