|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Bearing success |

| Home> | Efficient Maintenance | >Bearings | >Bearing success |

Bearing success

07 October 2013

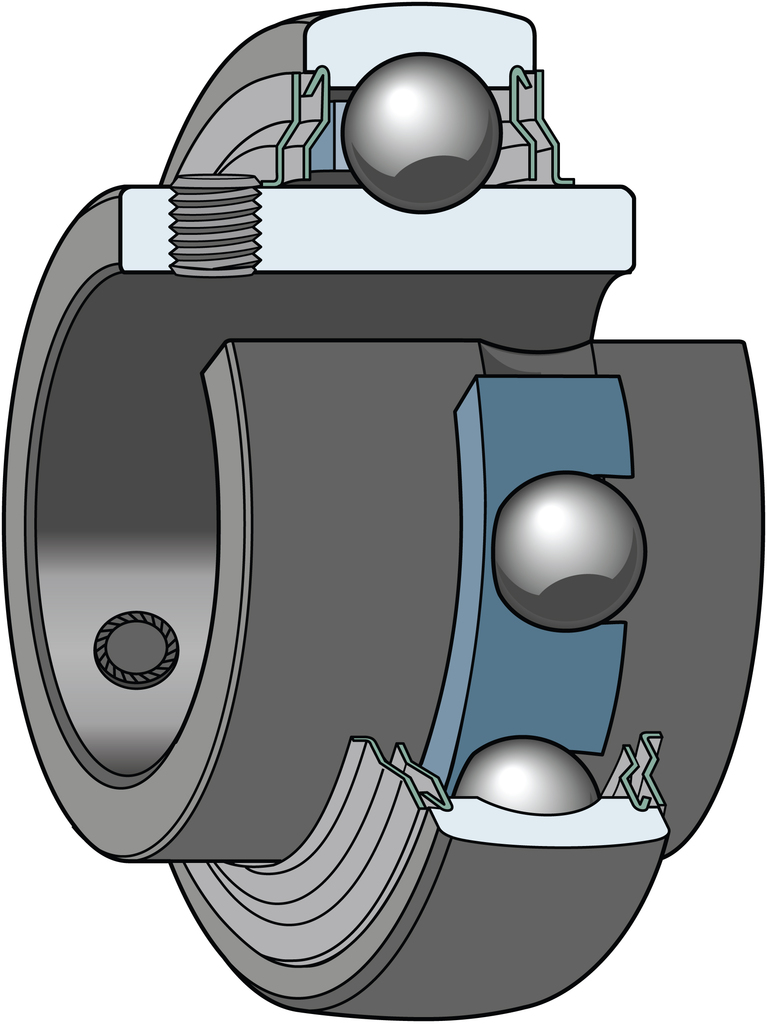

SKF has extended meantime between failure for British baking firm Warburtons from six months to three years with its extreme temperature Y-bearings (insert bearings), a dry lubrication option that removes the need for high temperature greases.

One area in which Warburtons wanted to increase efficiency was in the ovens at its Enfield site, where oven unloaders transport trays of product on rollers throughout the day. This process depends on the use of resilient bearings that can cope with regular temperatures to 120°C (and local temperatures to 200°+ if unloader trays jam).

SKF's VA228 bearings have a graphite cage that releases minute amounts of graphite powder to lubricate the bearing, offering an efficient dry lubricant option for low-speed, high temperature applications such as ovens.

The reduced costs of work related to repairs, manual lubrication, product or component consumption, and lubricant consumption achieved by installing SKF Y-bearings totals almost £7k/year; the total benefits of MTBF against costs are expected to deliver a return on investment of 200%.

- Seals for the wind market

- Digital production process introduced for bearings

- Efficient lubrication strategy?

- Bearing responsibility

- Ongoing quest for better bearings

- Shaft alignment tool

- Induction heater for large bearings

- New European aeronautical test centre

- Machine tool monitoring solution

- Correct lubricants: Key to performance