|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Motors and drives | >Oil costs reduced |

ARTICLE

Oil costs reduced

04 March 2013

Aberthaw Power Station in Wales is saving £350,000 on oil costs following the installation of ABB variable speed drives (VSDs).

Aberthaw Power Station in Wales is

saving £350,000 on oil costs

following the installation of ABB

variable speed drives (VSDs).

To light the coal-fired boilers, the power station which is operated by RWE npower, uses 36 oil-injecting lances on each of its three boilers. Oil from the lances is blown into the boiler by fans at two rates: a high flow rate to light the coal and a low flow rate to sustain and support the burn.

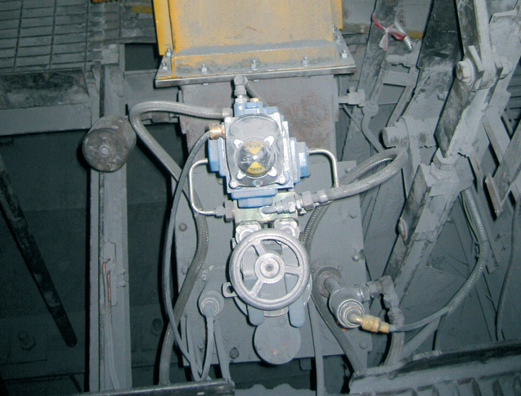

Fans were driven by direct on-line motors, but the power station found it difficult to get the correct oil flow rate, so Kevin Smyth, assistant electrical engineer, investigated using VSDs and found that the ABB drive had the required robustness for the challenging environment.

ABB Drives Alliance member, APDS of Bristol, recommended installation of ABB 7.5kW standard drives. A total of 32 were installed on oil injecting lances. The drives enable the motors to run at either of two speeds and have resulted in a saving of £350,000 on oil costs.

To light the coal-fired boilers, the power station which is operated by RWE npower, uses 36 oil-injecting lances on each of its three boilers. Oil from the lances is blown into the boiler by fans at two rates: a high flow rate to light the coal and a low flow rate to sustain and support the burn.

Fans were driven by direct on-line motors, but the power station found it difficult to get the correct oil flow rate, so Kevin Smyth, assistant electrical engineer, investigated using VSDs and found that the ABB drive had the required robustness for the challenging environment.

ABB Drives Alliance member, APDS of Bristol, recommended installation of ABB 7.5kW standard drives. A total of 32 were installed on oil injecting lances. The drives enable the motors to run at either of two speeds and have resulted in a saving of £350,000 on oil costs.

MORE FROM THIS COMPANY

- Tata Steel solves tricky temperature device upgrade

- Precise process control

- New features

- Supportive service

- Factory size doubled

- ABB Robotics welcomes Expert Technologies Group to UK Value Provider network

- Tool takes uncertainty out of flow measurement

- Team effort

- Smartphone Apps for VSDs

- Power options

OTHER ARTICLES IN THIS SECTION