|

Edward Lowton

Editor |

|

| Home> | Efficient Maintenance | >Maintenance products | >Problem avoided |

ARTICLE

Problem avoided

04 March 2013

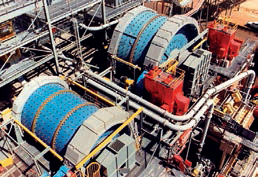

A raw mill at a cement manufacturers UK site has maintained vital production throughput, due to the swift response of a diagnostic monitoring and back-up service from Siemens Mechanical Drives.

A raw mill at a cement manufacturer's

UK site has maintained vital

production throughput, due to the

swift response of a diagnostic

monitoring and back-up service

from Siemens Mechanical Drives.

The company had a programme of pro-active maintenance in place and opted for a condition monitoring service from Siemens for the drive unit running the raw mill. The Siemens Combiflex DMGH is 2.5m tall by 1m wide. At its heart was a Flender girth gear. The monitoring service ensured regular checks were made on bearings, vibration analysis and wear characteristics.

During a routine check the early stages of potential bearing failure were found and shutdown was scheduled.

A spare gear unit kept on site was installed; the other unit was returned to Siemens for bearing and seal change before being returned to site.

The company had a programme of pro-active maintenance in place and opted for a condition monitoring service from Siemens for the drive unit running the raw mill. The Siemens Combiflex DMGH is 2.5m tall by 1m wide. At its heart was a Flender girth gear. The monitoring service ensured regular checks were made on bearings, vibration analysis and wear characteristics.

During a routine check the early stages of potential bearing failure were found and shutdown was scheduled.

A spare gear unit kept on site was installed; the other unit was returned to Siemens for bearing and seal change before being returned to site.

MORE FROM THIS COMPANY

- New generation of controllers

- Integrated drive systems: The quest for peak performance

- Service details

- Siemens partners with leading Irish systems integrators

- Siemens to inspire science engagement in five million young people

- Integrated drive solution boosts reliability at power station

- Whole package helps drive wind turbines

- Tackling the skills gap

- Malt manufacturer signs up to cost-cutting digital programme

- Connecting business and academia

OTHER ARTICLES IN THIS SECTION