|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Process equipment | >Plastics process optimised |

ARTICLE

Plastics process optimised

04 March 2013

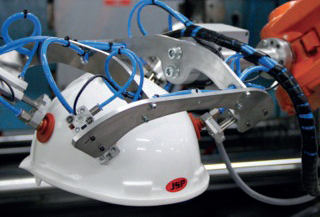

A new cooling system, designed, supplied and installed by Coolmation, is helping to optimise the efficiency of the plastics processing operation for manufacturer of health and safety products, Johnstone Safety Products (JSP).

A new cooling system,

designed, supplied and

installed by Coolmation, is

helping to optimise the

efficiency of the plastics

processing operation for

manufacturer of health and

safety products, Johnstone

Safety Products (JSP).

As part of a recent upgrade JSP installed 11 new CNC controlled, fast-cycle injection moulding machines. JSP had been a customer of Coolmation in the past and looked to the company to meet the hydraulic and tool cooling needs of the new machines.

Coolmation recommended a new 78kW air-cooled Rhoss chiller featuring two scroll compress ors, alongside a free cooling unit and a 90kW dry air cooling unit. This system is designed to meet specific plant requirements for machine tool and hydraulic motor cooling, enabling each injection-moulding machine to operate at its optimum level.

As part of a recent upgrade JSP installed 11 new CNC controlled, fast-cycle injection moulding machines. JSP had been a customer of Coolmation in the past and looked to the company to meet the hydraulic and tool cooling needs of the new machines.

Coolmation recommended a new 78kW air-cooled Rhoss chiller featuring two scroll compress ors, alongside a free cooling unit and a 90kW dry air cooling unit. This system is designed to meet specific plant requirements for machine tool and hydraulic motor cooling, enabling each injection-moulding machine to operate at its optimum level.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION