|

Edward Lowton

Editor |

|

| Home> | Energy Management | >Sustainable energy | >Testing role for chillers |

ARTICLE

Testing role for chillers

25 January 2013

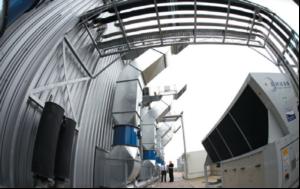

Coolmation has supplied a cooling system for new engine test cells at JCB Power Systems' plant in Derbyshire. Test cells require very accurately controlled parameters to perform the development work required to meet f

Coolmation has supplied a cooling

system for new engine test cells at JCB

Power Systems' plant in Derbyshire.

Test cells require very accurately controlled parameters to perform the development work required to meet future emissions legislation. Since each cell requires cooling in two areas at different temperatures, Coolmation's brief was to design a system which could be installed in two phase, combining within each phase, air blast cooling and water chilling.

Coolmation's initial cooling system incorporated two adiabatic coolers, one 440kW and one 800kW for the general engine cooling and a 180kWRhoss TCAEY BT air cooled chiller for the combustion air cooling.

Rhoss TCAEY BT 4230 air cooled chillers were selected because the full load will eventually be spread across eight scroll compressors, four in each chiller, which will enhance load matching and energy consumption.

Each of the TCAEY chillers has Rhoss's predictive control system, Adaptive Function Plus, which can reduce the energy consumption of the chillers by as much as 18%.

Test cells require very accurately controlled parameters to perform the development work required to meet future emissions legislation. Since each cell requires cooling in two areas at different temperatures, Coolmation's brief was to design a system which could be installed in two phase, combining within each phase, air blast cooling and water chilling.

Coolmation's initial cooling system incorporated two adiabatic coolers, one 440kW and one 800kW for the general engine cooling and a 180kWRhoss TCAEY BT air cooled chiller for the combustion air cooling.

Rhoss TCAEY BT 4230 air cooled chillers were selected because the full load will eventually be spread across eight scroll compressors, four in each chiller, which will enhance load matching and energy consumption.

Each of the TCAEY chillers has Rhoss's predictive control system, Adaptive Function Plus, which can reduce the energy consumption of the chillers by as much as 18%.

MORE FROM THIS COMPANY

OTHER ARTICLES IN THIS SECTION