|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Fasteners, springs and adhesives | >Flat springs: Burr and stress-free for safety critical applications |

ARTICLE

Flat springs: Burr and stress-free for safety critical applications

04 March 2013

Precision Micro reports an upturn in demand for flat springs as a result of the increasing popularity of specialist Martensitic stainless chrome steels, such as Sandvik 7c27mo2.

Precision Micro reports an

upturn in demand for flat

springs as a result of the

increasing popularity of specialist

Martensitic stainless chrome steels,

such as Sandvik 7c27mo2.

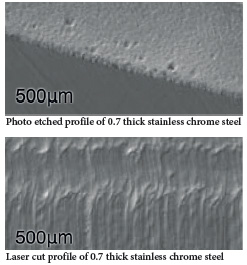

Traditionally flat springs have been stamped or laser cut. Precision Micro says blanking can create deformation, stressing the material and compromising flatness and that laser cutting is a thermal process that can cause heat stress and leave rough edges that could be initiation points for fatigue fracture if not removed completely. Both generate burrs.

Precision Micro's standard chemical machining process is said to produce perfectly flat springs and to impose no stress on the material.

The burr-free parts are said to have an exceptional edge finish with no lips, pits or surface imperfections that could become points for fatigue fracture. In addition, the company can offer 100% automated optical inspection that ensures components are within agreed dimensional limits.

Stand F22

Traditionally flat springs have been stamped or laser cut. Precision Micro says blanking can create deformation, stressing the material and compromising flatness and that laser cutting is a thermal process that can cause heat stress and leave rough edges that could be initiation points for fatigue fracture if not removed completely. Both generate burrs.

Precision Micro's standard chemical machining process is said to produce perfectly flat springs and to impose no stress on the material.

The burr-free parts are said to have an exceptional edge finish with no lips, pits or surface imperfections that could become points for fatigue fracture. In addition, the company can offer 100% automated optical inspection that ensures components are within agreed dimensional limits.

Stand F22

MORE FROM THIS COMPANY

- Precision Micro provides record apprentice placements

- UK etching specialist wins major filter contract for premium German appliance manufacturer

- Micro-etched components

- Responsible for worldwide sales

- Photochemical etching delivers enhanced efficiency for heat exchanger flow plates

- 5 year agreement

- Inconel: The good, the bad and the right approach

OTHER ARTICLES IN THIS SECTION