|

Edward Lowton

Editor |

|

ARTICLE

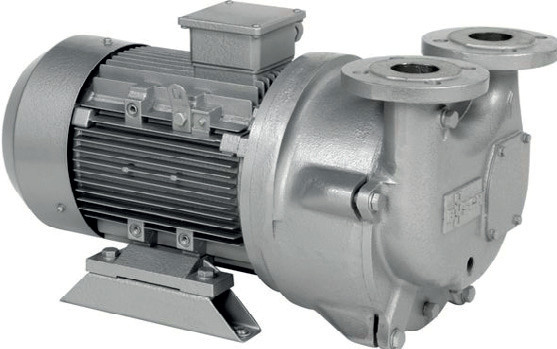

Liquid ring pump test facility

17 April 2013

Busch (UK) has unveiled a new liquid ring vacuum pump test facility at its Telford site, which offers a number of features and benefits for customers.

Busch (UK) has unveiled a new

liquid ring vacuum pump test

facility at its Telford

site, which offers a

number of features

and benefits for

customers.

The state-of-the-art rig has been designed specifically for the testing of liquid ring vacuum pump equipment that is in for repair and service, as well as for new custom built systems to ensure they meet all customer required factory acceptance tests (FATs). Key equipment featured includes a Piccolo flow measurement system, a power supply with 110kW inverter drive, and an external water storage tank with a seal water flow of 40 to 25,000l/h. Dedicated computerised sizing software enables production of flow characteristic curves for repaired liquid ring vacuum pumps. An extensive selection of couplings, fittings and accessories allows for the testing of pump equipment from any manufacturer.

The state-of-the-art rig has been designed specifically for the testing of liquid ring vacuum pump equipment that is in for repair and service, as well as for new custom built systems to ensure they meet all customer required factory acceptance tests (FATs). Key equipment featured includes a Piccolo flow measurement system, a power supply with 110kW inverter drive, and an external water storage tank with a seal water flow of 40 to 25,000l/h. Dedicated computerised sizing software enables production of flow characteristic curves for repaired liquid ring vacuum pumps. An extensive selection of couplings, fittings and accessories allows for the testing of pump equipment from any manufacturer.

MORE FROM THIS COMPANY

- 47% of employers report a technical skills gap

- €60 million for Europe’s innovators

- Project to assess impact of COVID-19 on factory hygiene

- IP&E: In the beginning…

- Her Majesty Queen Elizabeth II passes away

- How welders deal with magnetism in the component

- Manufacturing activity shows slight recovery but is still weak

- Deep learning brings simplicity to complex AI inspection

- Understanding preventive maintenance

- Software helps cuts costs of Ex inspections

RELATED ARTICLES

- No related articles listed

OTHER ARTICLES IN THIS SECTION