|

Edward Lowton

Editor |

|

| Home> | Handling and Storing | >Labelling, marking and barcoding | >Marked cut in downtime |

| Home> | Efficient Maintenance | >Maintenance products | >Marked cut in downtime |

Marked cut in downtime

06 June 2013

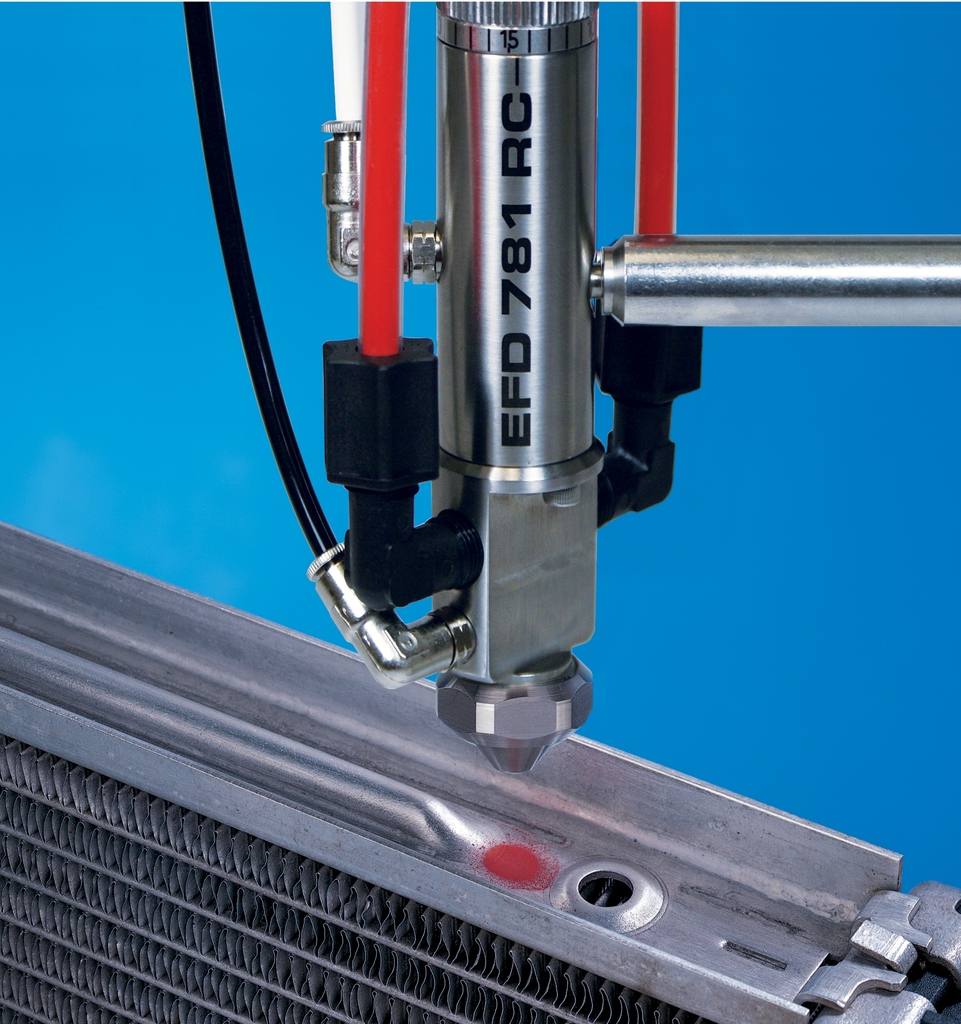

A non-contact ink marking system is helping an automotive component manufacturer reduce maintenance and downtime.

The company formerly used contact marking systems that fed ink to a felt wick pressed against the part. These systems required frequent maintenance whenever the wick dried out or picked up debris from the parts being marked.

After researching several options, they switched to the MicroMark spray marking system from Nordson EFD. Unlike contact marking systems, the MicroMark applies ink with a Low Volume Low Pressure (LVLP) precision spray valve that never touches the part. The change immediately reduced maintenance and downtime by eliminating the wear and contamination issues encountered with the felt wicks.

The MicroMark system can produce uniform spots between 5 and 30.4mm in diameter, depending on nozzle size and distance from the part.