|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Materials | >New material for slewing rings |

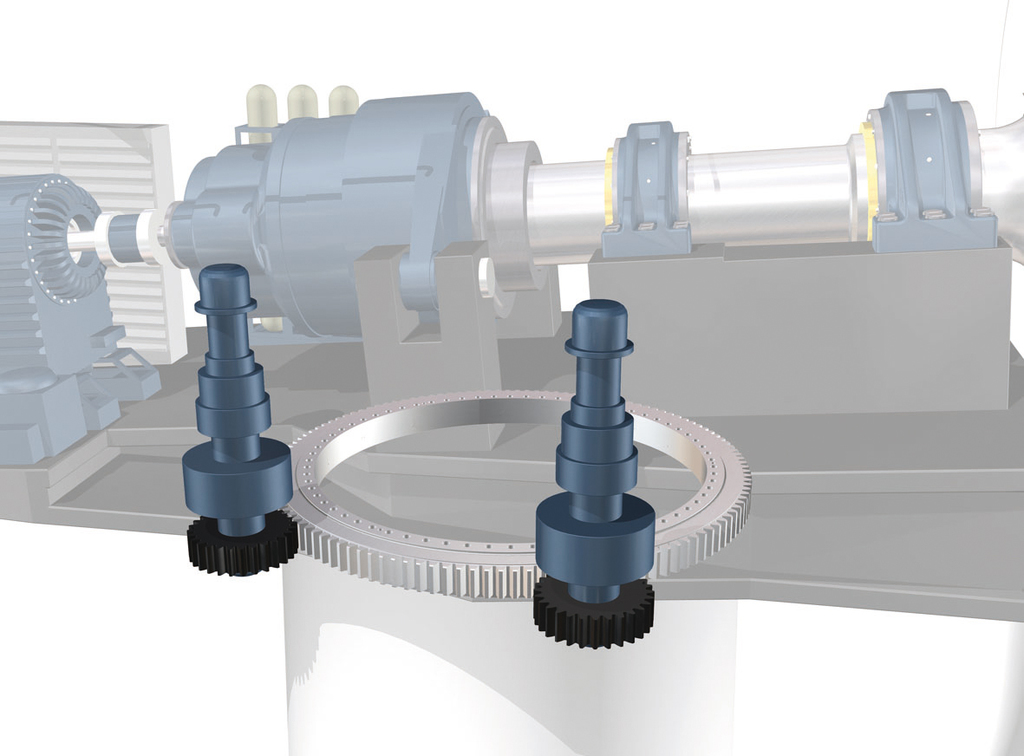

New material for slewing rings

30 May 2013

By working closely with the steel industry, bearings and condition monitoring specialist Schaeffler has co-developed a new, high strength quenched and tempered steel specifically for wind turbine slewing rings that are subjected to extreme loads during blade and tower adjustment.

This new material allows full tempering and quenching of the steel and is said to provide outstanding strength properties, even with large ring cross sections. Zinc thermal spray surfaces, multi-layer painting and finished seal surfaces also provide the high levels of reliability, bearing rating life and security against premature damage, such as fatigue of the raceways and surface corrosion. Due to the material properties and the applied surface protection, the bearings are suitable for use in ambient temperatures down to -40°C.

- Designed for all-electric and hybrid vehicles

- Plummer block housings for conveyors and turbines

- Bearing selection

- Versatile monitoring for wind turbine rotor bearings

- Driven linear actuators

- Counterfeit awareness campaign

- Split sphericals save €220,000 for chemical plant

- More counterfeit bearings seized

- Successful cooperation

- Split spherical roller bearings help cut costs for car maker