|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Bearings | >Split sphericals save €220,000 for chemical plant |

| Home> | Efficient Maintenance | >Bearings | >Split sphericals save €220,000 for chemical plant |

Split sphericals save €220,000 for chemical plant

28 November 2013

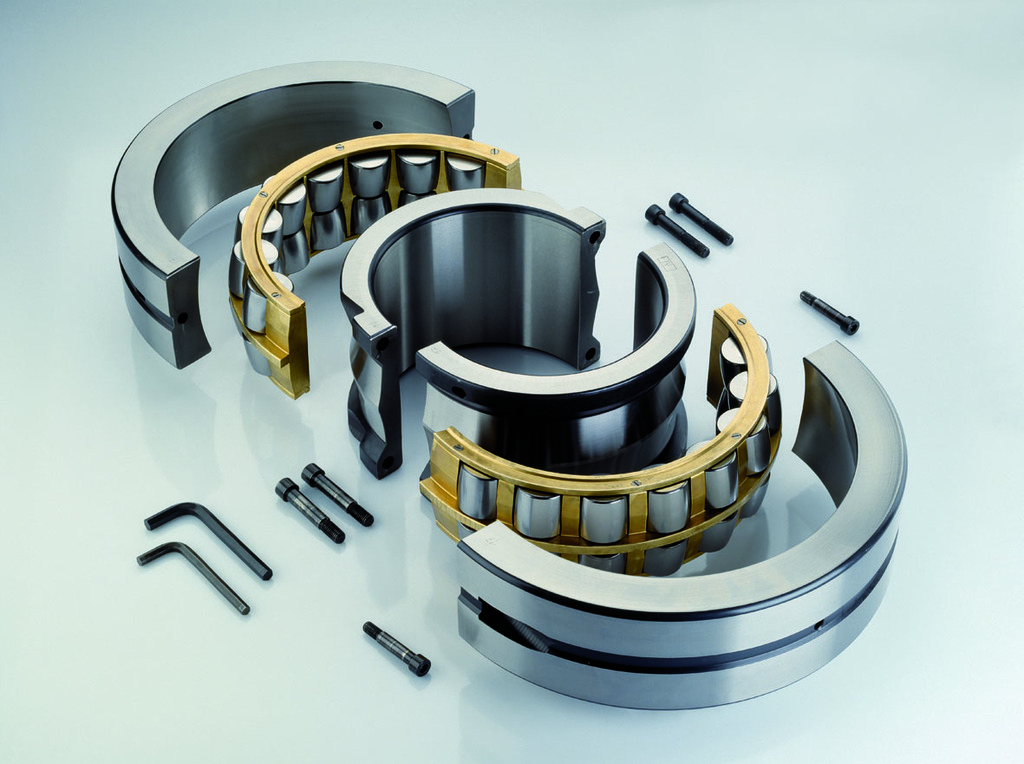

By replacing a solid spherical roller bearing on an exhaust gas fan with a split spherical roller bearing from Schaeffler, a chemical plant has saved €220,000.

The solid spherical roller bearing, which had an outside diameter of 230mm, needed replacing urgently. In the past, if the bearings were worn or damaged, the customer replaced these with similar solid (unsplit) spherical roller bearings. Each bearing replacement resulted in 14h of downtime, which cost around €280,000. This figure not only included the cost of production downtime, but the additional costs relating to labour, alignment of the shaft, crane hire and the costs of an additional replacement bearing.

By replacing the solid spherical roller bearing with a split spherical roller bearing from Schaeffler, the chemical plant reduced downtime to just 3h, with overall costs of €60,000. The costs of additional alignment, crane hire and a replacement bearing were not required this time, so the customer saved about €220,000 by using split spherical roller bearings.

- Successful cooperation

- Conveyor motor bearings run reliably at opencast mine

- Augmented reality support service

- Innovations for all-electric & hybrid vehicles

- Improve your skills and knowledge on rolling bearings and condition monitoring

- Bearing selection

- Designed for all-electric and hybrid vehicles

- Vibration monitoring and analysis service

- Technical pocket guide

- Online monitoring