|

Edward Lowton

Editor |

|

| Home> | Production Engineering | >Fasteners, springs and adhesives | >Spring solutions |

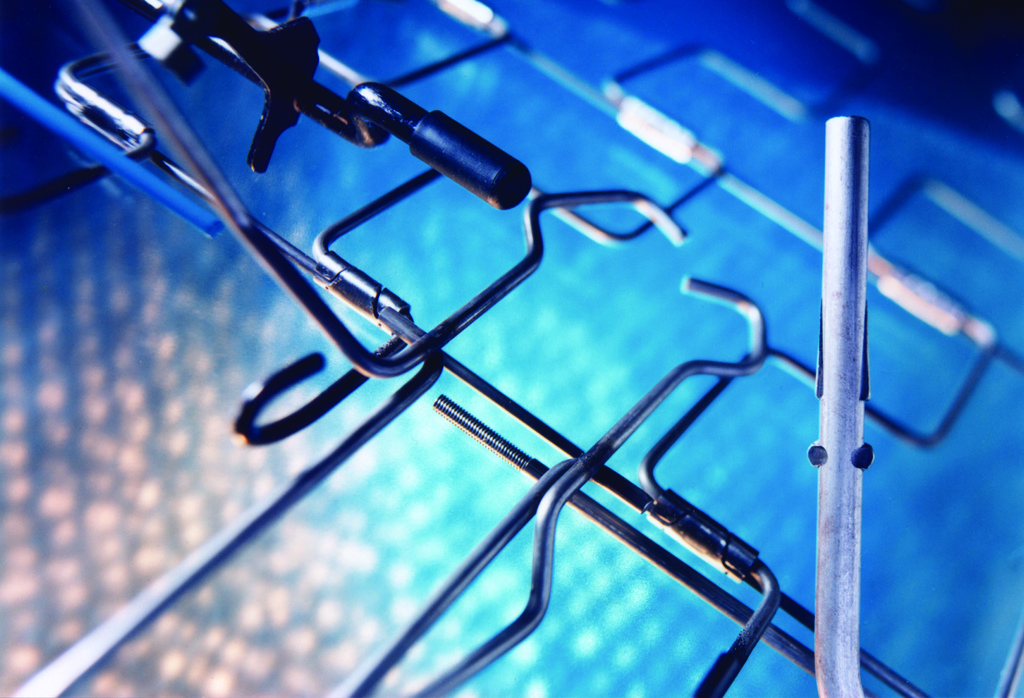

Spring solutions

06 June 2013

With an engineering heritage that stretches back to before the industrial revolution, William Hughes has over 200 years experience and expertise in the manufacture of springs and wire forms.

Today, William Hughes' resources are among the most extensive and sophisticated in Europe. Continuous investment in the most advanced equipment, much of it CNC based, combined with its in-house engineering resources, ensures a technical capability that is at the front end of what is possible today.

Modern materials and new technologies have provided new opportunities for William Hughes’ engineering team to design and manufacture springs and wire forms in a range of materials for small runs or volume production. The variety of springs and wire forms available is almost infinite and computerisation allows the production of highly intricate shapes which would have previously been impossible to consider. The choice of materials includes stainless steel, brass, phosphor bronze, beryllium copper and nickel chrome alloys.

- Celebrating success in Bulgaria

- Passivation explained and demonstrated

- European operations expanded

- Passivation plant added

- High performance springs for aerospace applications

- Acquisition announced

- Electrophoretic painting for protection of metal parts

- Rapid prototyping

- Offering plasma welding expertise

- Double torsion springs handle car maker's needs