|

Edward Lowton

Editor |

|

| Home> | Plant, Process & Control | >Pumps | >Aseptic series |

Aseptic series

18 September 2013

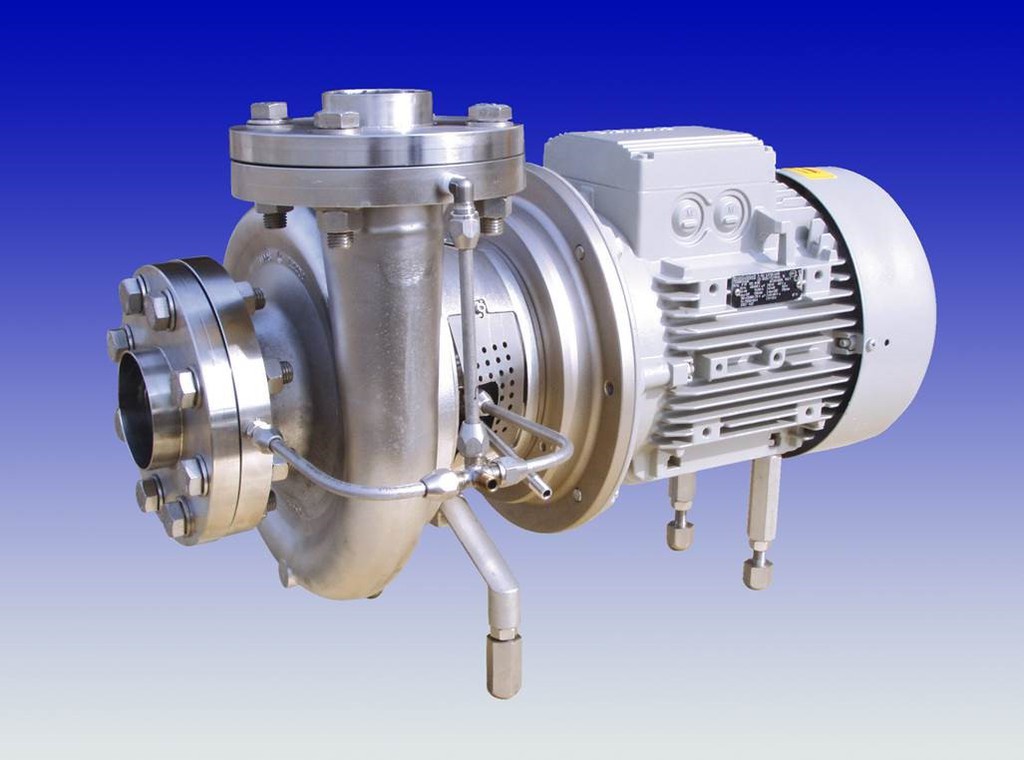

Available through Pump Engineering, the established range of CSF hygienic centrifugal pumps includes the CSD Aseptic series which achieves a very high level of hygiene when transferring liquids in food, beverage, pharmaceutical, injectable/intravenous, ultra pure and other process applications where hygiene is critical.

When fitted within an Aseptic plant these pumps ensure sterility and can assist in extending shelf life by ensuring the cleanest possible process conditions.

The mechanical seal is internal and balanced, fitted with EN12756/ISO3069 seats protected from contamination by a high temperature flush. Inlet and outlet ports are fitted with a steam protection barrier to ensure sterility, ensuring all points of potential microbial ingress are securely defended.

The CSD features an open impeller and a clamp casing, seal design and back pull out IEC standard motors, which allows for quick disassembly and inspection. These close coupled pumps are designed on a modular concept. An extensive performance range covers capacities from 1 to 300m3/h at heads up to 100m, with low NPSHr.

CSF CSD pumps are manufactured in electro-polished investment cast AISI 316L stainless steel, with stainless steel for all wetted parts. They are also available in Sanicro 28, Duplex SAF 2507 and Hastelloy C276 and with an optional 0.5 micron Ra surface finish. Elastomers are available in a choice of Viton, EPDM, or PTFE.

Typical applications for CSF CSD hygienic pumps include aseptic / long life food, beverage and milk products, injectable and intravenous products, pharmaceutical/biopharm, fine fragrances and flavourings where cross contamination and/or microbial ingress cannot be tolerated.